- marketing-sales@tozen.com

- +6327 116 4865

- 0917 569 2698

- 0917 6271947

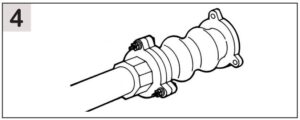

Twin-Sphere Screwed Type Flexible Rubber Joint

High Efficiency for Vibration and Noise Isolation

The twin sphere makes the spring constant small, decreases the body natural frequency and increases the efficiency of vibration absorption.

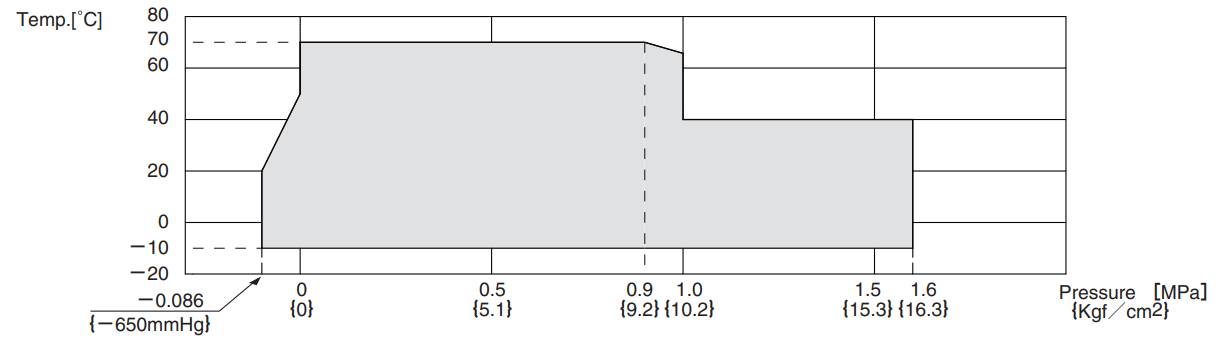

Withstandability

It can withstand a bursting pressure of over 5.0MPa and a maximum working pressure of 1.6MPa and with the combination of excellent formative technique and strong chemical fibre.

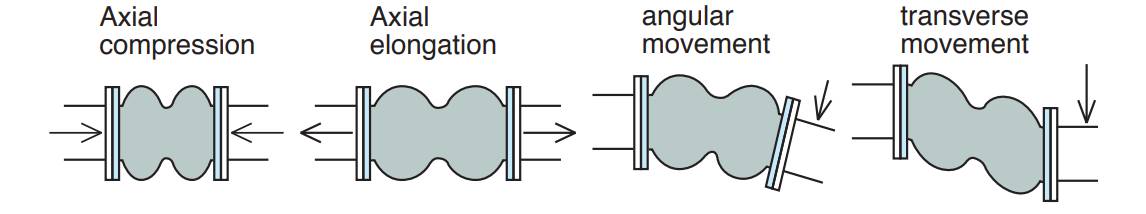

Large Displacement Absorption for Eccentricity, Axial Movement and Angular Movement

Since it can absorb large displacement, TWINFLEX screwed type flexible rubber joint is most appropriate for the protection of pipe line system. For example, it can prevent the destruction of connecting pipe due to earthquake and subsidence of ground.

Applicable for both Suction and Delivery

The joint fits for both suction and delivery.

Highly Reliable

The packing parts are strengthened with steel reinforcing rings to prevent the rubber body from slipping out of the fitting sides of flanges.

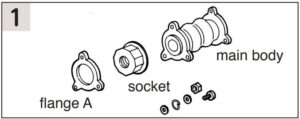

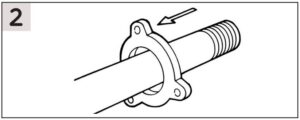

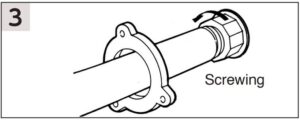

Convenient to install

When limited space is allowed for installation, the free type sockets can be screwed separately to pipe before fitting in the joint.

Durability

Reciprocating pressure test for 20,000 cycles or above.

● This product is mainly applicable for piping systems in commercial and industrial buildings and plants.

● Applicable fluids are exclusively water including cold water, warm water, cooled water, sea water, etc.

● This product can not be used for drinking water, pool water, oil, or boiled water.

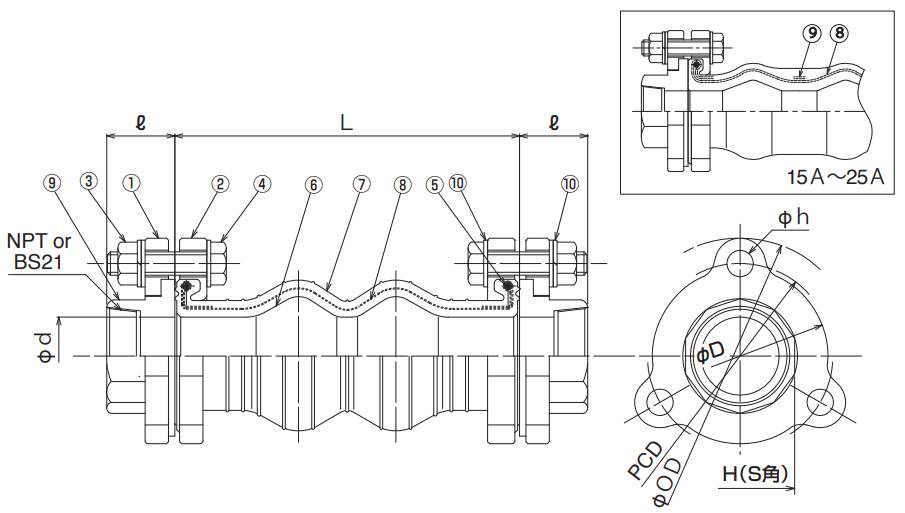

| No. | Parts | Material |

|---|---|---|

| 1 | Flange-A | Ductile Iron |

| 2 | Flange-B | Ductile Iron |

| 3 | Nut | Mild Steel |

| 4 | Bolt | Mild Steel |

| 5 | Reinforcing Cord | Synthetic Fiber |

| 6 | Inner Rubber | Synthetic Fiber |

| 7 | Outer Rubber | Synthetic Fiber |

| 8 | Reinforcing Cord | Synthetic Fiber |

| 9 | Union Edge | Ductile Iron |

| 10 | Washer | Mild Steel |

● The material of No.1, 2 & 9 can be changed to SUS304 and SUS316.

● The product is also applicable for oil use by changing the rubber material.

If need be, please contact us.

| Nominal Dia. | Dimension [mm] | Mass [Kg] | Union Edge [mm] | Flange [mm] | Allowable Movement [mm] | Installation Tolerances [mm] | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | L | φd | ℓ | Rc | H | φD | PCD | φh | φOD | T.M. | A.E. | A.C. | A.M. | T.M. | A.E. | A.C. | A.M. | |

| 15 | 1/2 | 120 | 25 | 30 | 1.7 | 1/2 | 41 | 68 | 70 | 11.0 | 93 | 15 | 10 | 15 | 15 |

6 | 3 | 6 | 7.5 |

| 20 | 3/4 | 120 | 25 | 30 | 1.8 | 3/4 | 41 | 68 | 70 | 11.0 | 93 | 15 | 10 | 15 | 15 |

6 | 3 | 6 | 7.5 |

| 25 | 1 | 120 | 25 | 30 | 1.9 | 1 | 41 | 68 | 70 | 11.0 | 93 | 15 | 10 | 15 | 15 |

6 | 3 | 6 | 7.5 |

| 32 | 1 1/4 | 175 | 35 | 35 | 3.1 | 1 1/4 | 50 | 90 | 95 | 13.5 | 121 | 20 | 10 | 15 | 20 |

8 | 3 | 6 | 7.5 |

| 40 | 1 1/2 | 175 | 35 | 35 | 3.3 | 1 1/2 | 56 | 90 | 95 | 13.5 | 121 | 20 | 10 | 15 | 20 |

8 | 3 | 6 | 7.5 |

| 50 | 2 | 175 | 45 | 40 | 5.4 | 2 | 69 | 106 | 110 | 13.5 | 135 | 20 | 10 | 15 | 20 |

8 | 3 | 6 | 7.5 |

・A.C.: Axial Compression, A.E.: Axial Elongation,

A.M.: Angular Movement, T.M.: Transverse Movement

・Tolerances for installation are included in the allowable movements

(Allowable movements = Tolerances for installation + Operating movements).

・Please note that the information in the above table is for single movement only.

In case of complex movements, please do adjustment by using the following formula.

C.A.E. (C.A.C.) = A.A.E.(A.A.C.) × {1-(T.M / A.T.M. + A.M. /A.A.M)}

C.A.E. (C.A.C.): Correct Elongation Movement (Correct Compression Movement)

A.A.E. (A.A.C.): Allowable Elongation Movement (Allowable Compression Movement)

A.T.M.: Allowable Transverse Movement A.A.M.: Allowable Angular Movement

Example: In case of 50mm joint, if 10mm transverse movement is needed, then the correct elongation should be: C.A.E = 10 × {1- (10/20 + 0/20)} = 5mm

・There is reaction force from rubber joints due to the load of the internal pressure, so during the installation, please use the metal fittings to fix the pipe tightly to ensure the joints work efficiently. In case the pipe cannot be fixed tightly, please use the control unit for the joints.

Note: The content of this catalog is subject to change without prior notice.