- marketing-sales@tozen.com

- +6327 116 4865

- 0917 569 2698

- 0917 6271947

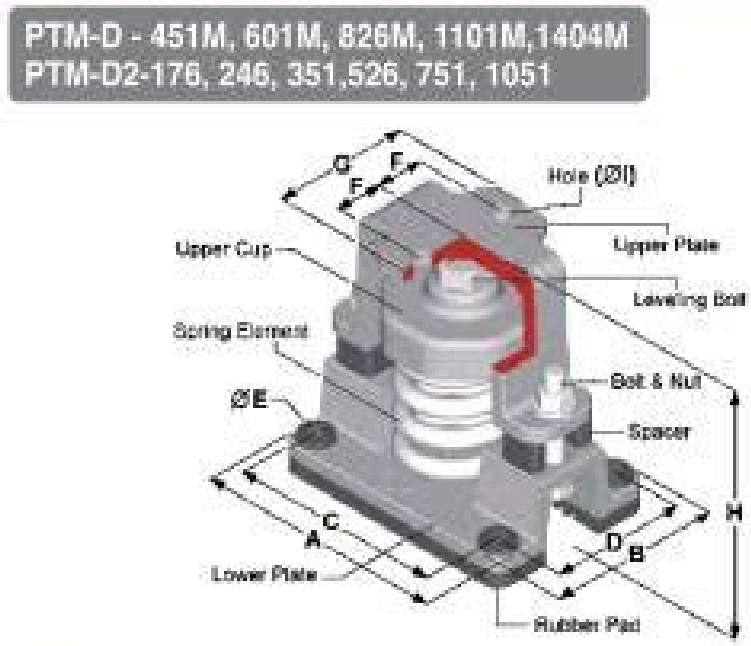

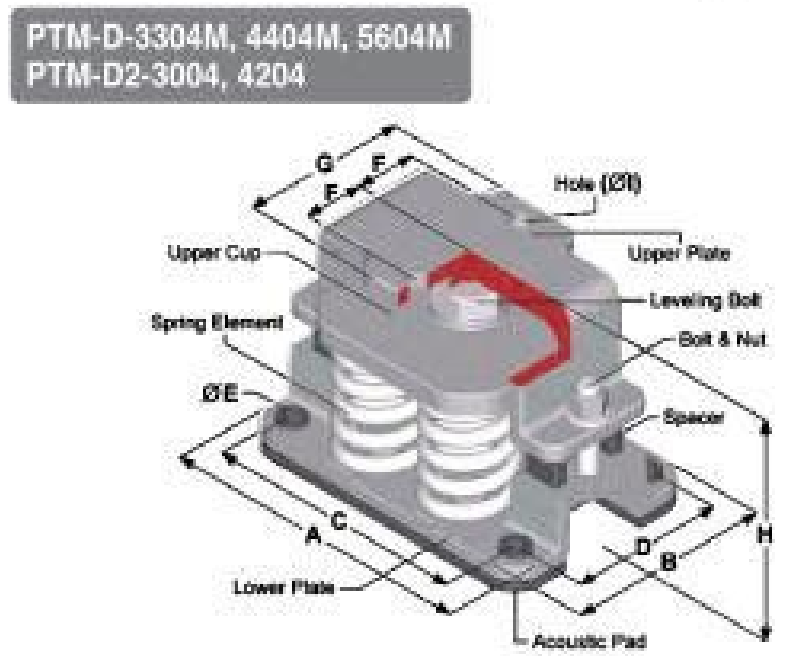

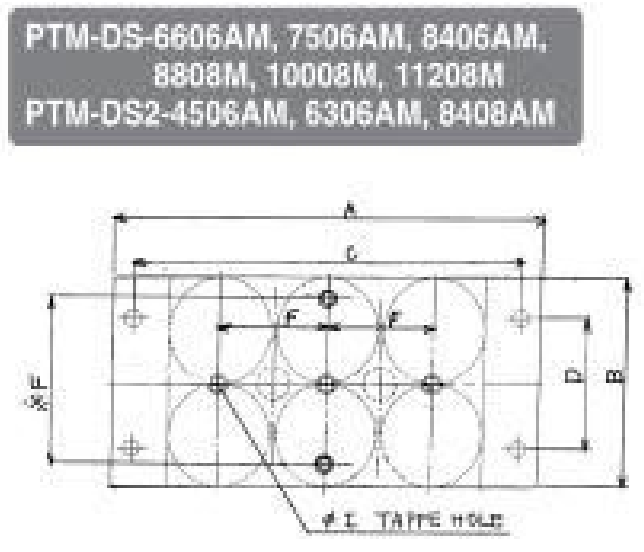

Restrained single and multiple spring isolator

TOZEN PTM-D series vibration isolators consist of free standing laterally stable steel springs assembled into ductile iron housing assemblies fabricated to limit vertical movement of the isolated equipment’s when if equipment loads are reduced or if the equipment’s are subjected to large external forces. Spring elements are complete with an internal adjusting and leveling bolt. Holes are provided at the upper plate for bolting to supported equipment. A 10mm thick non-skid noise absorbing rubber pad is bonded at the bottom plate with holes for bolting to the structure. All the spring elements are comply to JIS 2704 for semi-permanent use. To assure lateral stability, outside diameter of the spring elements do not less than 0.8 times of the compressed height of the spring at rated load. All the spring are designed to provide a minimum of 50% overload capacity.

PTM-D series vibration isolator are shipped with standard deflections of 25 and 50 mm, and available up to 50mm, with load capacities from 450 Kgs to 5,600 Kgs. Model PTM-D spring isolators are recommended for the isolation of vibration produced by equipment carrying a large fluid load which may be drained, such as boilers and chillers, and for the isolation of cooling towers, air cooled condensers, etc., where motion due to wind loads must be minimized.

Type PTM-D mounts are typically used to reduce the transmission of noise and vibration into supporting structures from equipment’s carrying a large fluid load that may be drained, such as boilers and for cooling towers, which also require hold down for wind loads.

Vibration isolators for equipment which is subject to load vibrations and large external or torquing forces shall consist of laterally stable steel springs assembled into a ductile iron in housing assembly designed to limit vertical movement of the supported equipment.

Housing assembly shall be of ductile iron members and consist of a load transfer plate at the top complete with holes, adjusting and leveling bolts, vertical restraints, isolation washers and a bottom plate with non-skid noise isolation pad and holes provided for anchoring to supporting structure.

Spring elements shall have a outside diameter not less than 0.8 times to the compressed height of the spring rated load. All springs shall be designed to provide a minimum of 50% overload capacity.

PTM-D TYPE

25mm DEFLECTION RESTRAINED SPRING ISOLATOR

| MODEL | RATED CAPACITY | SPRING CONSTANT (kgs/mm) |

SPRING COLOR | OPERATING HEIGHT (H) |

DIMENSION (MM) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (Lbs) | A | B | C | D | ØE | F | G | ØI | ||||

| PTM-D-450M | 450 | 990 | 18 | GREEN | 170 | 172 | 121 | 137 | 86 | 16 | 30 | 88 | 14 |

| PTM-D-601M | 600 | 1320 | 24 | SILVER | |||||||||

| PTM-D-826M | 825 | 1815 | 33 | BROWN | |||||||||

| PTM-D-1101M | 1100 | 2420 | 44 | BLUE | |||||||||

| PTM-D-1401M | 1400 | 3080 | 56 | BLUE+BROWN | |||||||||

| PTM-D-1652M | 1650 | 3630 | 66 | BROWN | 170 | 180 | 200 | 136 | 156 | 20 | 40 | 118 | 18 |

| PTM-D-2202M | 2200 | 4540 | 88 | BLUE | |||||||||

| PTM-D-2802M | 2800 | 6160 | 112 | BLUE+BROWN | |||||||||

| PTM-D-3304M | 3300 | 7260 | 132 | BROWN | 185 | 255 | 167 | 211 | 1235 | 20 | 48.5 | 135 | 18 |

| PTM-D-4404M | 4400 | 9680 | 176 | BLUE | |||||||||

| PTM-D-5604M | 5600 | 12320 | 224 | BLUE+BROWN |

NOTE-1: All springs are free standing and laterally stable. (Outside diameter do not less 0.8 times of compressed height)

NOTE-2: All springs are designed to provide additional travel to solid of at least 50 rated load.

NOTE-3: Please refer to relevant brochure or factory for greater deflection and loading

PTM-DS TYPE

25mm DEFLECTION RESTRAINED SPRING ISOLATOR

| MODEL | RATED CAPACITY | SPRING CONSTANT (kgs/mm) |

SPRING COLOR | OPERATING HEIGHT (H) |

DIMENSION (MM) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (Lbs) | A | B | C | D | ØE | F | G | ØI | ||||

| PTM-DS-4956MA | 4950 | 10890 | 198 | BROWN | 205 | 420 | 175 | 380 | 100 | 20 | 110 | – | M16x3 |

| PTM-DS-6606MA | 6600 | 14520 | 264 | BLUE | |||||||||

| PTM-DS-7506MA | 7500 | 16500 | 300 | BLUE+WHITE | |||||||||

| PTM-DS-8406MA | 8400 | 18480 | 335 | BLUE+BROWN | |||||||||

| PTM-DS-8808MA | 8800 | 19360 | 352 | BLUE | 205 | 475 | 175 | 435 | 100 | 20 | 115 (ØF |

– | M16x2 |

| PTM-DS-10008MA | 10000 | 22000 | 400 | BLUE+WHITE | |||||||||

| PTM-DS-11208MA | 11200 | 24640 | 448 | BLUE+BROWN |

NOTE-1: All springs are free standing and laterally stable. (Outside diameter do not less 0.8 times of compressed height)

NOTE-2: All springs are designed to provide additional travel to solid of at least 50 rated load.

NOTE-3: Please refer to relevant brochure or factory for greater deflection and loading

NOTE-4: PTM-DS is carbon steel type

PTM-D2 TYPE

50mm DEFLECTION RESTRAINED SPRING ISOLATOR

| MODEL | RATED CAPACITY | SPRING CONSTANT (kgs/mm) |

SPRING COLOR | OPERATING HEIGHT (H) |

DIMENSION (MM) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (Lbs) | A | B | C | D | ØE | F | G | ØI | ||||

| PTM-D2-176 | 175 | 385 | 3.5 | ORANGE | 210 | 190 | 130 | 152 | 95 | 16 | 38 | 106 | 16 |

| PTM-D2-246 | 245 | 539 | 4.9 | VIOLET | |||||||||

| PTM-D2-351 | 350 | 770 | 7 | RED | |||||||||

| PTM-D2-526 | 525 | 1155 | 10.5 | GREEN | |||||||||

| PTM-D2-751 | 750 | 1650 | 15 | SILVER | |||||||||

| PTM-D2-1051 | 1050 | 2310 | 21 | SILVER+BROWN | 210 | 232 | 196 | 187 | 152 | 20 | 42 | 120 | 16 |

| PTM-D2-1502 | 1500 | 3300 | 30 | SILVER | |||||||||

| PTM-D2-2102 | 2100 | 4620 | 42 | SILVER+BROWN | |||||||||

| PTM-D2-3004 | 3000 | 600 | 60 | SILVER | 220 | 300 | 200 | 250 | 162 | 20 | 66.5 | 170 | 20 |

| PTM-D2-4204 | 4200 | 9240 | 84 | SILVER+BROWN |

NOTE-1: All springs are free standing and laterally stable. (Outside diameter do not less 0.8 times of compressed height)

NOTE-2: All springs are designed to provide additional travel to solid of at least 50 rated load.

NOTE-3: Please refer to relevant brochure or factory for greater deflection and loading

PTM-DS2 TYPE

50mm DEFLECTION RESTRAINED SPRING ISOLATOR

| MODEL | RATED CAPACITY | SPRING CONSTANT (kgs/mm) |

SPRING COLOR | OPERATING HEIGHT (H) |

DIMENSION (MM) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (Lbs) | A | B | C | D | ØE | F | G | ØI | ||||

| PTM-DS2-4506MA | 4500 | 9900 | 90 | SILVER | 250 | 430 | 207 | 390 | 132 | 20 | 110 | – | M16X3 |

| PTM-DS2-6306MA | 6300 | 13860 | 126 | SILVER+BROWN | |||||||||

| PTM-DS2-8408MA | 8400 | 18480 | 168 | SILVER+BROWN | 250 | 540 | 207 | 500 | 132 | 20 | 147 (ØF) |

– | M16X3 |

NOTE-1: All springs are free standing and laterally stable. (Outside diameter do not less 0.8 times of compressed height)

NOTE-2: All springs are designed to provide additional travel to solid of at least 50 rated load.

NOTE-3: Please refer to relevant brochure or factory for greater deflection and loading

NOTE-4: PTM-DS is carbon steel type

1) Check that the internal leveling nut is adjusted up to underside of the upper plate.

2) Lift or block up the equipment to 5mm higher that isolator’s operating height (see catalogue) and slide the isolators into position and adjust the leveling nut until the upper plate is in contact with equipment base

Insert fastening screws (if used) through the equipment base into top of the mounting and tighten.

3) Check alignment of the base so that restraining bolts are central with clearance holes in the restraining bracket.

4) Transfer the equipment weight to the spring by taking two counter-clockwise turns on each leveling

bolt around the unit until springs are compressed just enough to remove blocks.

5) Adjust restraining nuts to give 2-3mm clearance between the restrain washer and the underside of the restraining bracket. Check the leveling again after the system is filled with water.

6)Tighten the lock nut to lock the assembly.

a) When the equipment are not subject to raise to the required height, height saving bracket may be attached to the equipment. The height of bracket connection from the bottom of the base shall be 50mm less than the isolator’s operating height or to keep a 50mm clearance between the ground and equipment.

b) DON’T install the equipment on the support of free spring, it would cause an insufficient operating height for the spring isolator when the installation is completed.

c) Weight of vertical piping and valves shall be taken over by the suspension hangers or support.

d) Install the flexible joint at final, follow the pre-extension instruction which may specified or suggested by the flexible joint manufacturer.

e) Where bolting is required, avoid a direct metal contact between bolt and mounting, to prevent transmission of acoustical frequencies; the bolt shank shall be clear in the hole and a rubber washer used under the bolt head. Bolts shall only be tightened a half turn more than hand tight.

Note: The contents of this catalogue are subject to change without notice.