- marketing-sales@tozen.com

- +6327 116 4865

- 0917 569 2698

- 0917 6271947

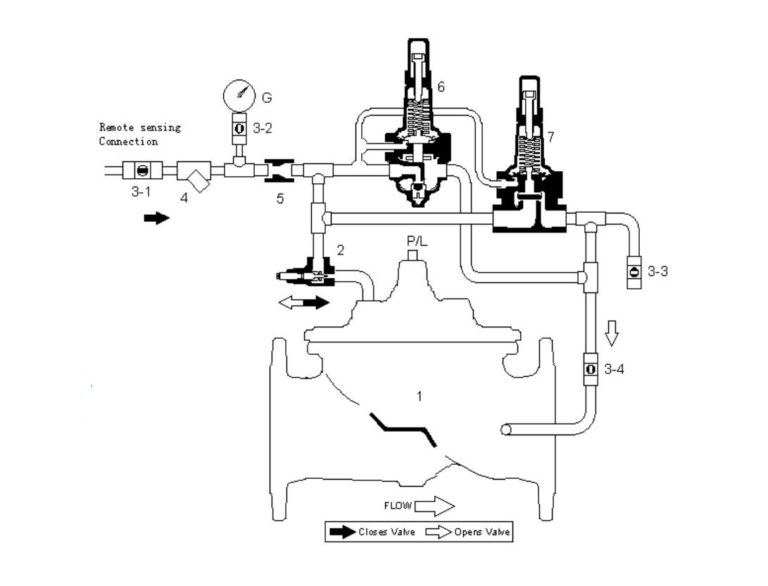

The Model 550 Surge Anticipator Valve is indispensable for protecting pumps, pumping equipment and all applicable pipelines from dangerous pressure surges caused by rapid changes of flow velocity within a pipeline.

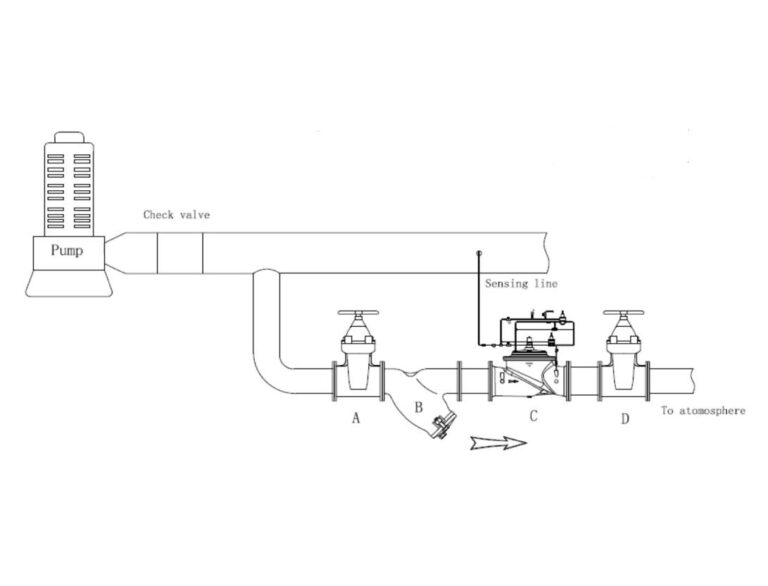

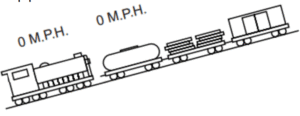

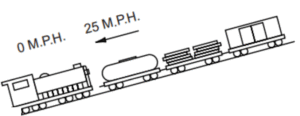

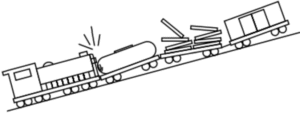

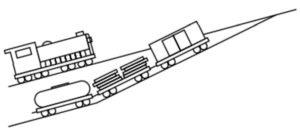

When pumping systems are started and stopped gradually, harmful surges do not occur. However, should a power failure take place, the abrupt stopping of the pump can cause dangerous surges in the system which could result in severe equipment damage. Power failure to a pump will usually result in a down surge in pressure, followed by an up surge in pressure. The surge control valve opens on the initial low pressure wave, diverting the returning high pressure wave from the system. In effect, the valve has anticipated the returning high pressure wave and is open to dissipate the damage causing surge. The valve will then close slowly without generating any further pressure surges.

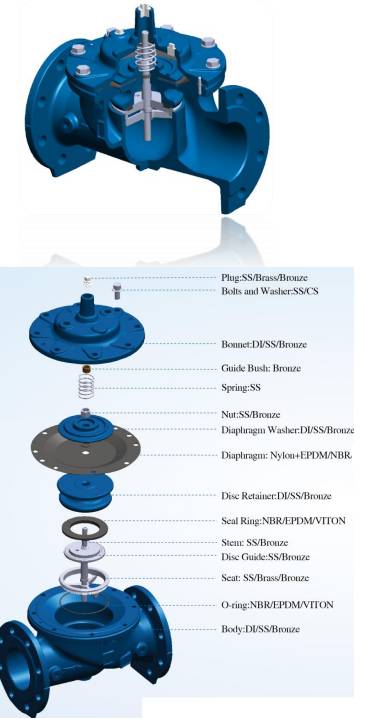

| Standard Features | Optional Features | Typical Applications |

|---|---|---|

| 1. Main valve 2. Needle valve 3. Ball valve 4. Strainer 5. Restriction 6. Lower pressure relief pilot 7. High pressure relief pilot |

B. Ball valve G. Pressure Gauge P. Position indicator L. Limit switch |

A. Inlet isolation valve B. Strainer C. Surge anticipating valve D. Outlet isolation valve |

Water Temperature

■ 0 – 80ºC

Working pressure

■ ISO PN 16: 16 bar

■ ISO PN 25: 25 bar

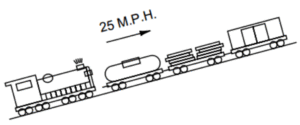

A. Without surge anticipating valve

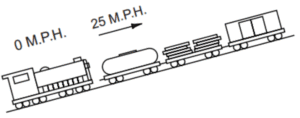

B. With surge anticipating valve, surge decreased

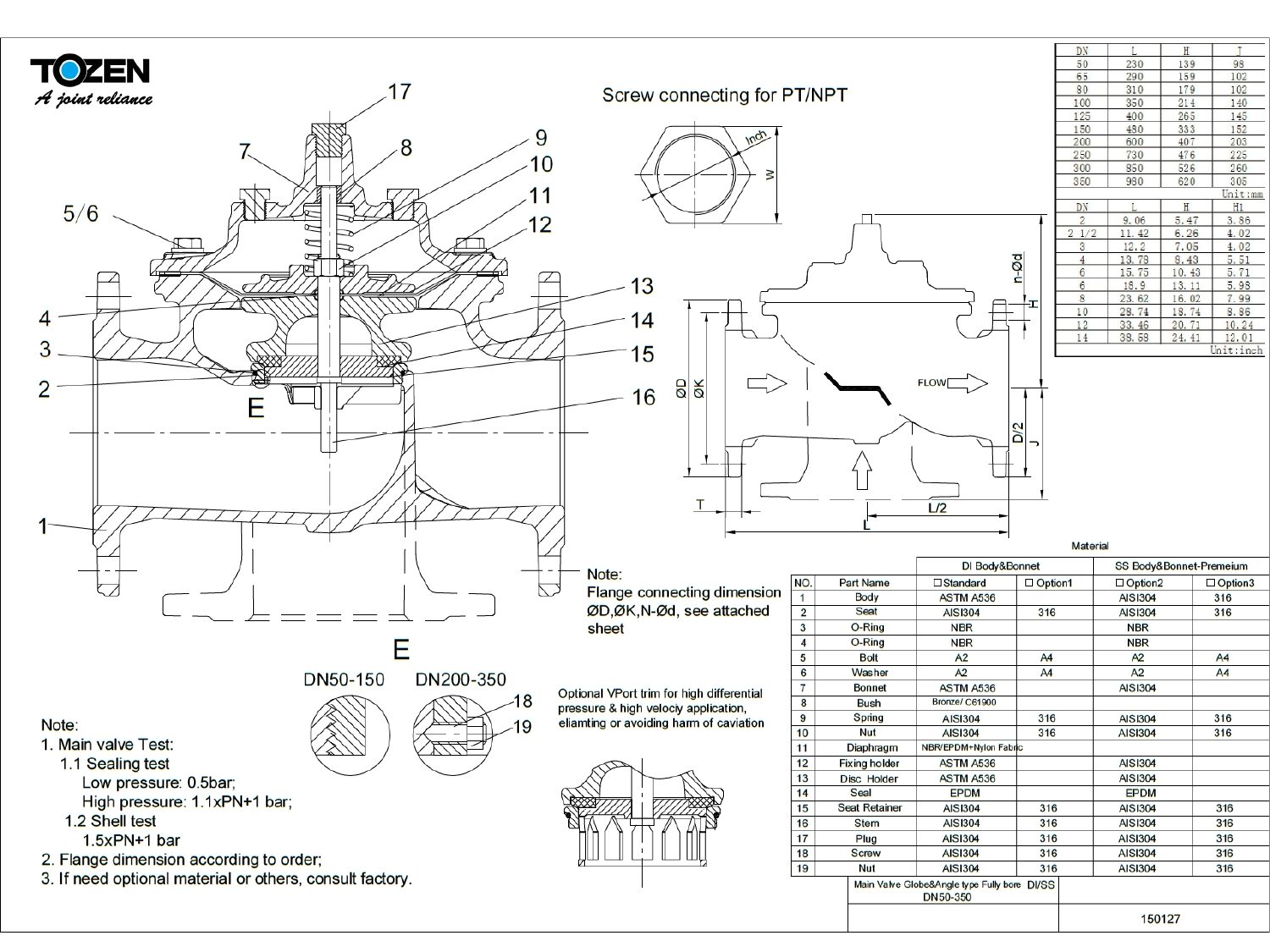

Main valve work cases and principle

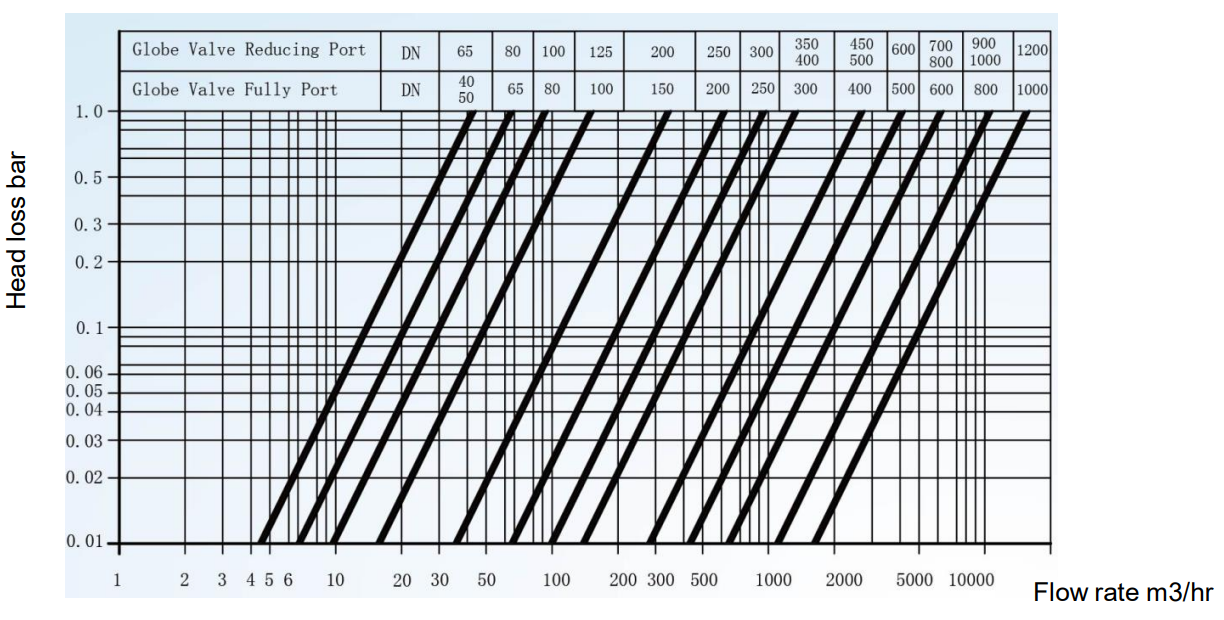

Flow curve of main valve fully open

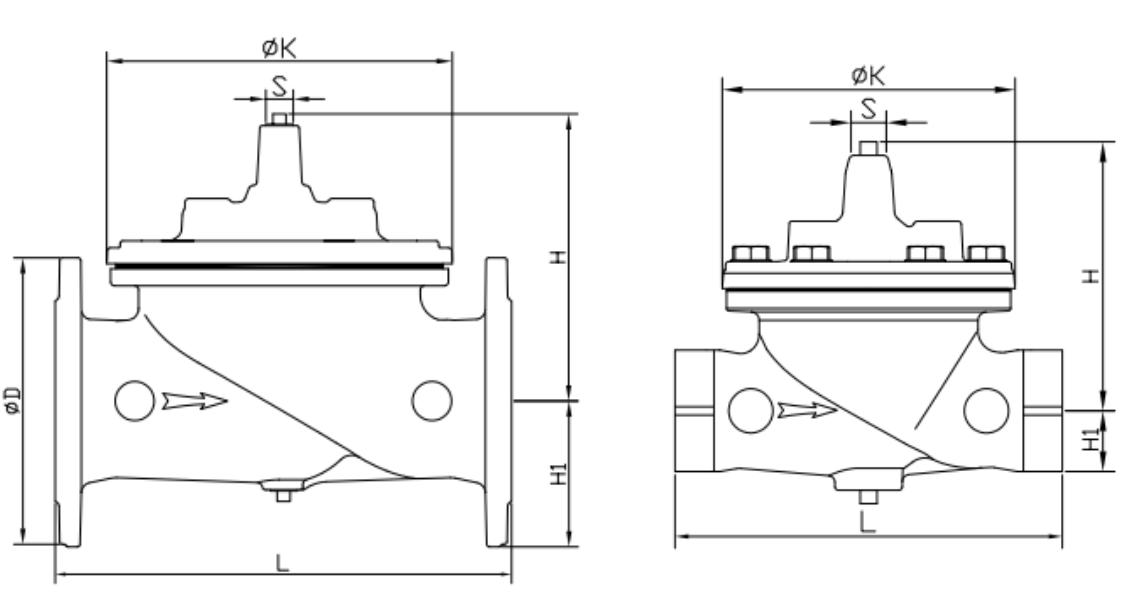

| DN | L | H | H1* | ФK | S | W (Kg) |

|---|---|---|---|---|---|---|

| 40 | 230 | 139 | 85 | 173 | 3/8″ | 14 |

| 50 | 230 | 139 | 85 | 173 | 3/8″ | 14 |

| 65 | 290 | 159 | 95 | 198 | 3/8″ | 19 |

| 80 | 310 | 179 | 102 | 226 | 3/8″ | 23 |

| 100 | 350 | 214 | 112 | 265 | 1/2″ | 32 |

| 125 | 400 | 278 | 127 | 307 | 1/2″ | 48 |

| 150 | 480 | 333 | 145 | 351 | 1/2″ | 68 |

| 200 | 600 | 407 | 172 | 436 | 3/4″ | 125 |

| 250 | 730 | 476 | 205 | 524 | 1″ | 200 |

| 300 | 850 | 526 | 232 | 606 | 1″ | 260 |

| 350 | 950 | 585 | 262 | 673 | 1″ | 405 |

| 400 | 1100 | 624 | 292 | 741 | 1″ | 560 |

| 500 | 1250 | 720 | 360 | 1002 | 1″ | 880 |

| 600 | 1450 | 835 | 425 | 1308 | 1″ | 1300 |

| 800 | 1850 | 1110 | 515 | 1755 | 1″ | 1950 |

| 1000 | 2250 | 1350 | 630 | 2231 | 1″ | 2456 |

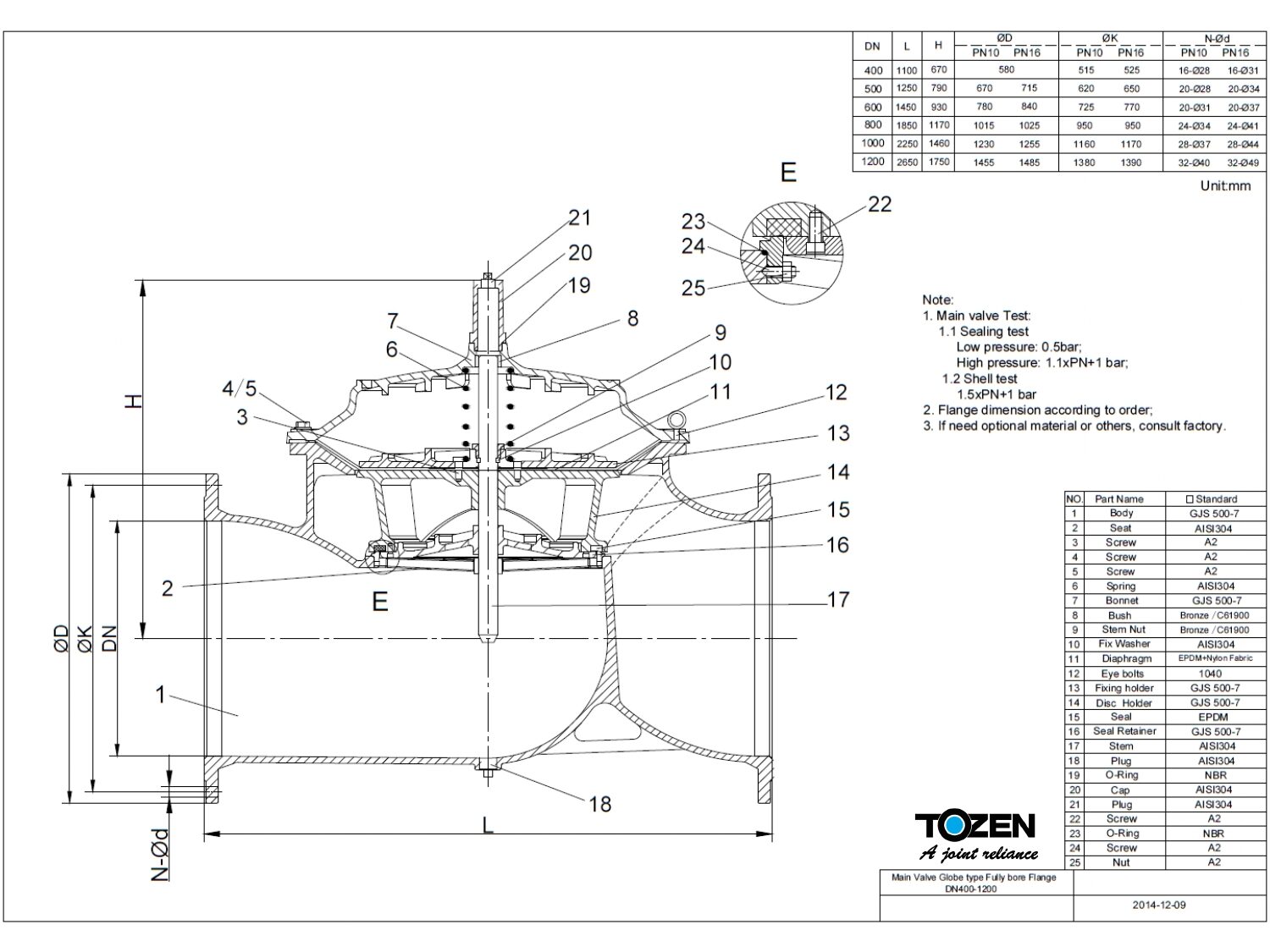

| DN | L | H | H1* | ФK | S | W (Kg) |

|---|---|---|---|---|---|---|

| 65 | 290 | 139 | 95 | 173 | 3/8″ | 15 |

| 80 | 310 | 159 | 102 | 198 | 3/8″ | 21 |

| 100 | 350 | 179 | 112 | 226 | 3/8″ | 27 |

| 125 | 400 | 214 | 127 | 265 | 1/2″ | 34 |

| 150 | 480 | 214 | 145 | 265 | 1/2″ | 37 |

| 200 | 600 | 333 | 172 | 351 | 1/2″ | 88 |

| 250 | 730 | 407 | 205 | 436 | 3/4″ | 144 |

| 300 | 850 | 476 | 232 | 524 | 1 | 231 |

| 350 | 980 | 526 | 262 | 606 | 1″ | 281 |

| 400 | 1100 | 526 | 292 | 606 | 1″ | 370 |

| 450 | 1200 | 624 | 325 | 741 | 1″ | 295 |

| 500 | 1250 | 624 | 360 | 741 | 1″ | 750 |

| 600 | 1450 | 720 | 425 | 1002 | 1″ | 1150 |

| 700 | 1650 | 835 | 460 | 1308 | 1″ | 1420 |

| 800 | 1850 | 835 | 515 | 1308 | 1″ | 1510 |

| 900 | 2050 | 1110 | 570 | 1755 | 1″ | 2185 |

| 1000 | 2250 | 1110 | 630 | 1755 | 1″ | 258 |

| 1200 | 2450 | 1350 | 750 | 2231 | 1″ | 3155 |

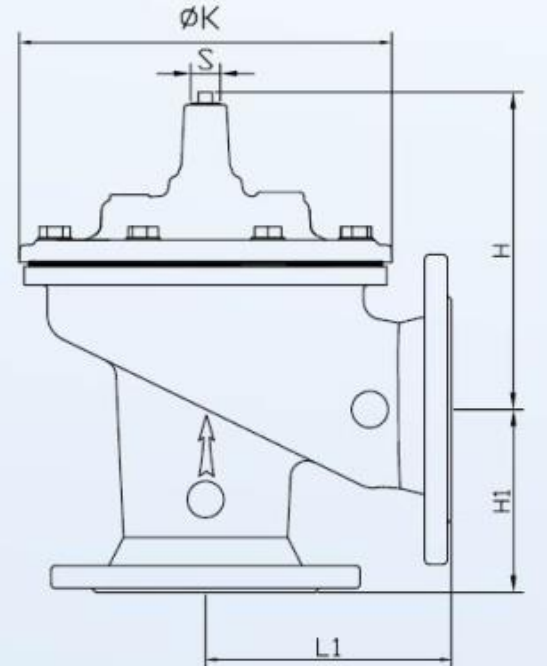

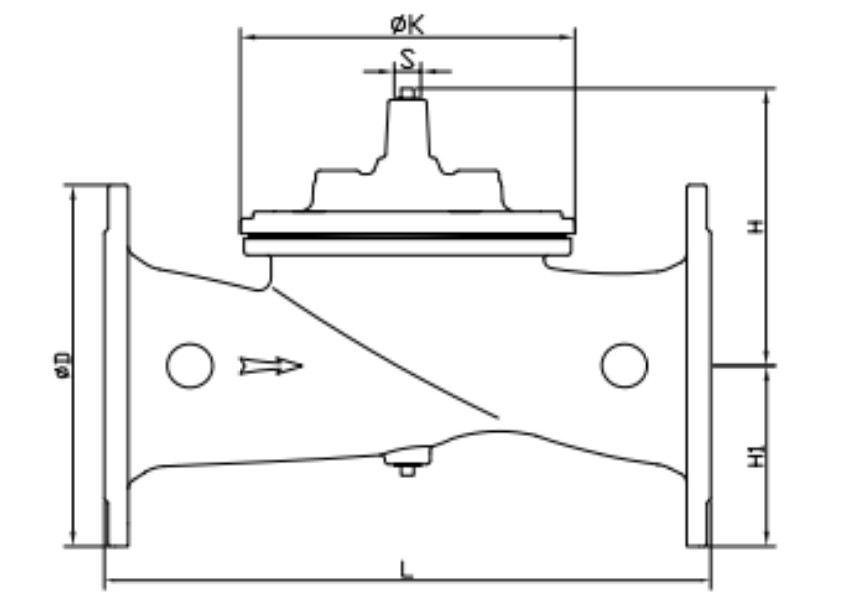

| DN | L1 | H | H1 | ФK | S | W (Kg) |

|---|---|---|---|---|---|---|

| 50 | 115 | 139 | 85 | 173 | 3/8″ | 13 |

| 65 | 145 | 159 | 95 | 198 | 3/8″ | 18 |

| 80 | 105 | 179 | 102 | 226 | 3/8″ | 21 |

| 100 | 175 | 214 | 135 | 265 | 1/2″ | 31 |

| 125 | 200 | 278 | 145 | 307 | 1/2″ | 46 |

| 150 | 240 | 333 | 150 | 351 | 1/2″ | 65 |

| 200 | 300 | 407 | 203 | 436 | 3/4″ | 121 |

| 250 | 365 | 476 | 225 | 524 | 1 | 195 |

| 300 | 425 | 526 | 260 | 606 | 1″ | 253 |

| 350 | 490 | 585 | 305 | 673 | 1″ | 399 |