- marketing-sales@tozen.com

- +6327 116 4865

- 0917 569 2698

- 0917 6271947

Floor mounting single spring isolator, Heavy loading multiple spring isolator

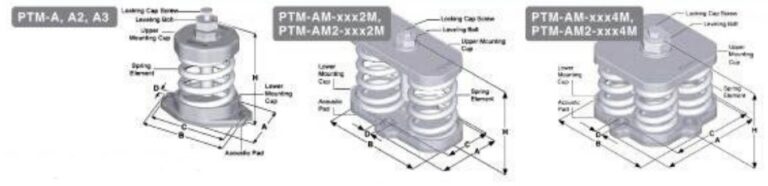

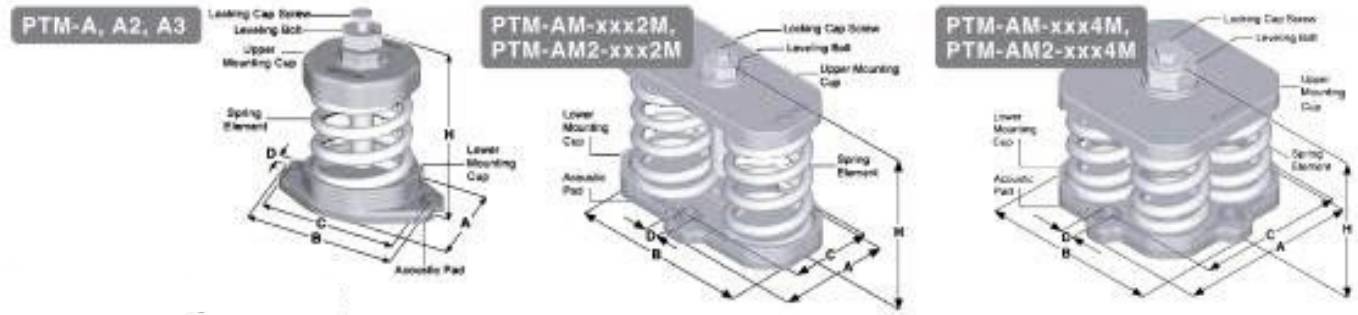

TOZEN Model PTM-A & PTM-AM series isolators are unhoused, spring, vibration isolators, designed for high deflection. The PTM-A employs the use of a single spring element, while the PTM-AM employs multiple spring elements for heavier applications. These laterally stable steel spring isolators are constructed with a leveling device at the top of the isolator and a non-skid acoustical pad at the bottom. Both models are constructed with upper and lower ductile cast iron holding cups to hold the spring element. In addition, on, PTM-A & PTM-AM have a mounting base plate to allow the isolator to be bolted to a structure and a resilient washer as part of the nonskid acoustical pad. The resilient washer helps prevent the transmission of noise and vibration from the base plate and mounting bolt to the structure.

The design off the spring elements, within the isolators, complies wit with established standard JIS B2704, for semipermanent use. To assure lateral stability, the outside diameter of the spring element is greater than 80% of the height of the compressed spring element when at rated load. All the spring elements are designed to provide a minimum of overloading capacity of 50%.

PTM-A & PTM-AM series vibration isolator are available in the standard deflections at 25 mm, and also available in deflections of 50 and 75 mm. Load capacity of the PTM-A isolators range from 25 to 1,400 Kgs (55 to 3080 lbs) and up to 5,600 Kgs (12320 lbs.) for PTM-AM isolators.

Tozen PTM-A & PTM-AM series of spring isolators are highly effective in the control of both high and low frequency vibrations produced by mechanical equipment, such as Reciprocating Air or Refrigeration Compressors, Pumps, Air Conditioning and Air Handling Equipment, Centrifugal and Axial Fans, Internal Combustion Engines and similar types of equipment.

PTM-A & PTM-AM series spring isolators are recommended for use in isolating floor mounted sources of noise and vibration located near critical quiet areas.

PTM-A series spring isolators are typically used to reduce the transmission of noise and vibration from low speed mechanical equipment into a building structure.

PTM-A & AM series spring isolators can be used in a wide range of applications involving the isolation of mechanical equipment, such as Reciprocating Air or Refrigeration Compressors, Close Coupled and Base Mounted Pumps, Package Air Handling and Refrigeration Equipment, Centrifugal Fans, Internal Combustion Engines and similar equipment.

The vibration isolators shall be free standing, with laterally stable steel spring elements, without housings, snubbers or guides. The isolators shall be constructed with the ductile cast iron upper mounting cup and the ductile cast iron lower mounting cup to hold the spring element, and a non-skid acoustical pad is attached atta under the lower cup. The isolators shall be provided with an adjusting bolt, cap screw and washer in top of the isolator for leveling and attachment to the equipment. The spring elements of the isolator shall have an outside diameter greater than 80% of the height of the compressed spring element at rated load. All spring elements shall be designed to provide a minimum overloading capacity of 50%.

The isolators shall be selected to provide operating static deflection shown on the Vibration Isolation Schedule or as indicated by the project specifications. Isolators shall be color coded or otherwise identified to indicate load capacity.

PTM-A, AM TYPE

25 mm DEFLECTION SINGLE & MULTIPLE SPRING VIBRATION ISOLATOR

| MODEL | RATED CAPACITY | SPRING CONSTANT (kg/mm) |

SPRING ELEMENT | OPERATING HEIGHT (H) |

DIMENSION (MM”) | LOCKING CAP SCREW (LS) | LEVELING BOLT (LB) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (Lbs) | SPRING COLOR | OD (mm) |

FREE HEIGHT (mm) |

A | B | C | D | |||||

| PTM-A-25S | 25 | 55 | 1.0 | WHITE | 50 | 80 | 120 | 61 | 107 | 89 | 10 | M10X32 | M16X70 |

| PTM-A-35S | 35 | 77 | 1.4 | YELLOW | |||||||||

| PTM-A-50S | 50 | 110 | 2.0 | ORANGE | |||||||||

| PTM-A-80S | 80 | 17 | 3.2 | VIOLET | |||||||||

| PTM-A-120S | 120 | 264 | 4.8 | RED | |||||||||

| PTM-A-175S | 175 | 385 | 7.0 | SILVER | |||||||||

| PTM-A-225S | 225 | 495 | 9.0 | BROWN | |||||||||

| PTM-A-200S | 200 | 440 | 8.0 | VIOLET | 75 | 100 | 150 | 88 | 13 | 117 | 13 | M12X43 | M22X80 |

| PTM-A-300S | 300 | 660 | 12.0 | RED | |||||||||

| PTM-A-450S | 450 | 990 | 18.0 | GREEN | |||||||||

| PTM-A-600S | 600 | 1320 | 24.0 | SILVER | |||||||||

| PTM-A-825S | 825 | 1815 | 33.0 | BROWN | |||||||||

| PTM-A-1100S | 1100 | 2420 | 44.0 | BLUE | |||||||||

| PTM-A-1400S | 1400 | 3080 | 56.0 | BLUE+BROWN | |||||||||

| PTM-A-1652S | 1650 | 3630 | 66.0 | BROWN | 75 | 100 | 144 | 112 | 198 | 75 | 14X18 | M12X43 | M22X80 |

| PTM-A-2202S | 2200 | 4840 | 88.0 | BLUE | |||||||||

| PTM-A-2802S | 2800 | 6160 | 112.0 | BLUE+BROWN | |||||||||

| PTM-A-3304S | 3300 | 7260 | 132.0 | BROWN | 75 | 100 | 152 | 197 | 197 | 11 | 14X18 | M16X45 | M30X90 |

| PTM-A-4404S | 4400 | 9680 | 176.0 | BLUE | |||||||||

| PTM-A-5604S | 5600 | 12320 | 224.0 | BLUE+BROWN |

NOTE-1:All springs are laterally stable and suitable for free standing application. (Outside diameter > 80 of detecting height)

NOTE-2: Please refer to relevant brochure or our technical division for greater deflection and loading.

PTM-A2, AM2 TYPЕ

50 mm DEFLECTION SINGLE & MULTIPLE SPRING VIBRATION ISOLATOR

| MODEL | RATED CAPACITY | SPRING CONSTANT (kg/mm) |

SPRING ELEMENT | OPERATING HEIGHT (H) |

DIMENSION (MM”) | LOCKING CAP SCREW (LS) | LEVELING BOLT (LB) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (mm) | SPRING COLOR | OD (mm) |

FREE HEIGHT (mm) |

A | B | C | D | |||||

| PTM-A2-25S | 25 | 55 | 0.5 | WHITE | 75 | 120 | 170 | 88 | 136 | 117 | 13 | M12X43 | M22X80 |

| PTM-A2-35S | 35 | 77 | 0.7 | YELLOW | |||||||||

| PTM-A2-50S | 50 | 110 | 10 | ORANGE | |||||||||

| PTM-A2-80S | 80 | 176 | 1.6 | VIOLET | |||||||||

| PTM-A2-125S | 125 | 275 | 2.5 | RED | |||||||||

| PTM-A2-175S | 175 | 385 | 3.5 | SILVER | |||||||||

| PTM-A2-250S | 250 | 550 | 5.0 | BROWN | |||||||||

| PTM-A2-175M | 175 | 385 | 3.5 | ORANGE | 90 | 145 | 195 | 101 | 155 | 130 | 13 | M12X43 | M22X115 |

| PTM-A2-245M | 245 | 539 | 4.9 | VIOLET | |||||||||

| PTM-A2-350M | 350 | 770 | 7.0 | RED | |||||||||

| PTM-A2-525M | 525 | 1155 | 10.5 | GREEN | |||||||||

| PTM-A2-750M | 750 | 1650 | 15.0 | SILVER | |||||||||

| PTM-A2-1050M | 1050 | 2310 | 21.0 | SILVER+BROWN | |||||||||

| PTM-A2-1502M | 1500 | 3300 | 30.0 | SILVER | 90 | 145 | 189 | 130 | 230 | 92 | 14X18 | M14X43 | M22X80 |

| PTM-A2-2102M | 2100 | 4620 | 42.0 | SILVER+BROWN | |||||||||

| PTM-A2-3004M | 3000 | 6600 | 60.0 | SILVER | 196 | 244 | 244 | 203 | 14X18 | M16X45 | M30X90 | ||

| PTM-A2-4204M | 4200 | 9240 | 84.0 | SILVER+BROWN |

NOTE-1:All springs are laterally stable and suitable for free standing application. (Outside diameter > 80 of detecting height)

NOTE-2: Please refer to relevant brochure or our technical division for greater deflection and loading.

PTM-A3, TYPE

75 mm DEFLECTION SINGLE & MULTIPLE SPRING VIBRATION ISOLATOR

| MODEL | RATED CAPACITY | SPRING CONSTANT (kg/mm) |

SPRING ELEMENT | OPERATING HEIGHT (H) |

DIMENSION (MM”) | LOCKING CAP SCREW (LS) | LEVELING BOLT (LB) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (mm) | SPRING COLOR | OD (mm) |

FREE HEIGHT (mm) |

A | B | C | D | |||||

| PTM-A3-180S | 180 | 396 | 2.4 | ORANGE | 90 | 170 | 220 | 101 | 155 | 130 | 13 | M12X43 | M22X115 |

| PTM-A3-255S | 255 | 561 | 3.4 | VIOLET | |||||||||

| PTM-A3-375S | 375 | 825 | 5.0 | RED |

NOTE-1:All springs are laterally stable and suitable for free standing application. (Outside diameter > 80 of detecting height)

NOTE-2: Please refer to relevant brochure or our technical division for greater deflection and loading.

1) Block or lift up the equipment to a level so that the equipment’s leg or base is 5 mm higher than isolator’s operating height (see cataloque). If common base & height saving isolator bracket is used, keep 50-mm clearance between the base and floor. Maintain this height until piping installation is completed.

2) Locate the spring isolator under the hole in equipment’s leg or isolator’s bracket. Connect locking caр crew and washer, but do not tighten.

3) Transfer the equipment weight to the spring by taking two counter-clockwise turns on each leveling bolt around the unit until springs are compressed just enough to remove the blocks.

4) Tighten the locking cap screw to lock the assembly.

a) DO NOT install the equipment on the support of a free spring. This will cause an insufficient operating height for the spring isolator when the installation is completed.

b) Weight of vertical piping and valves must to supported by the suspension hangers or supports.

c) Install the flexible joint at the end of the installation, following the pre-extension instruction which may specified or suggested by the flexible joint manufacturer.

d) Bolting down the isolator to the floor, in most cases, is not necessary as the non-slip rubber pad or mounting cup will prevent movement. Where bolting is required, avoid a direct metal contact between bolt and mounting, to prevent transmission of noise; the bolt shank shall be clear in the hole and a rubber washer used under the bolt head. Bolts shall only be tightened a half turn more than hand tight.

Note: The contents of this catalogue are subject to change without notice.