- marketing-sales@tozen.com

- +6327 116 4865

- 0917 569 2698

- 0917 6271947

Model : DDRV-B

DDRV-B25

65mm (21/2”) ~ 300mm (12”)

Tozen Double Regulating Valves are installed and used in centralized heating and cooling systems to obtain design flow rates of each terminal units and balancing the circuits in the building.

• Balancing

• Measuring

• Pre-setting

• Isolating

• Y-pattern globe design.

• Integral fixed orifice plate to form a fixed orifice flow measurement unit with regulation and isolation function.

• Accuracy of +/-5% at full open position of the valve.

• Equipped with 2 measuring nipples for differential pressure measurement.

• Microset handwheel adjustment with easily readable settings.

• Multi-turn adjustment range for maximum flow control.

• Double regulating feature allows valve opening to be set with allen key.

• Long neck for thermal insulation.

• Ductile iron body of PN16 & PN 25 pressure rating.

• Comply to BS 7350.

| Type | Fixed orifice |

| Size range | 65mm ~ 300mm |

| Max. working pressure | 16bar (DDRV-B) 25bar (DDRV-B25) |

| Testing pressure (Shell) | 24bar (DDRV-B) 37.5bar (DDRV-B25) |

| Testing pressure (Seat) | 17.6bar (DDRV-B) 27.5bar (DDRV-B25) |

| Working temperature | -10°C to 120°C |

| Connection | EN1092-2 PN16/25 (Other flange standard available upon request) |

| Standard | Comply to BS 7350 |

| Part | Material | ASTM | EN |

|---|---|---|---|

| Body | Ductile Iron | A536 65-45-12 | EN-JS 1050 |

| Bonnet | Ductile Iron | A536 65-45-12 | EN-JS 1050 |

| Stem | Stainless Steel 410 | S41000 | BS970 410S21 |

| Disc | EPDM Coated Ductile Iron | A536 65-45-12 | EN-JS 1050 |

| Gland (65 – 150mm) | DZR Brass | B453 C35330 | EN12165 CW602N |

| Gland (200 – 300mm) | Ductile Iron | A536 65-45-12 | EN-JS 1050 |

| Gland Nut | DZR Brass | B453 C35330 | EN 12164 CW602N |

| Measuring Nipples | DZR Brass | B453 C35330 | EN 12164 CW602N |

| Handwheel | Ductile Iron | A536 65-45-12 | EN-JS 1050 |

| Orifice Insert | DZR Brass | B453 C35330 | EN 12164 CW602N |

| Packing | EPDM | – | – |

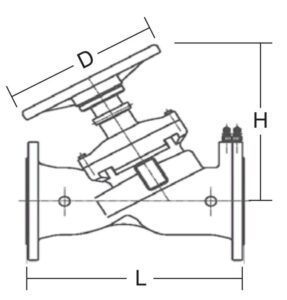

| Size (mm) |

L (mm) |

H (mm) |

D (mm) |

Weight (kg) |

Kvs |

|---|---|---|---|---|---|

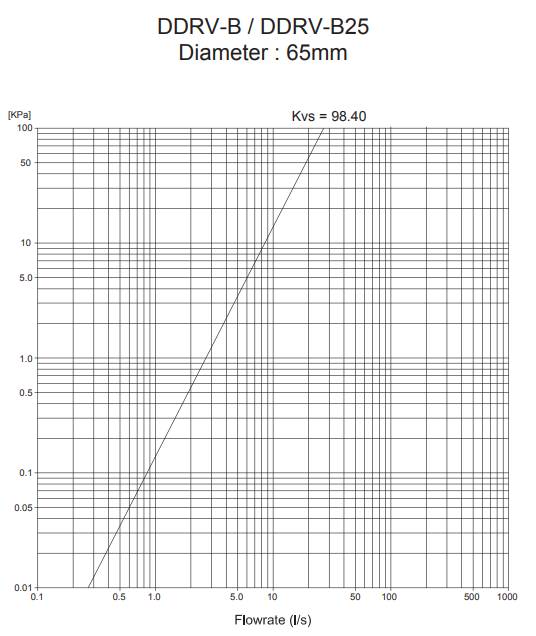

| 65 | 290 | 265 | 200 | 17 | 98.40 |

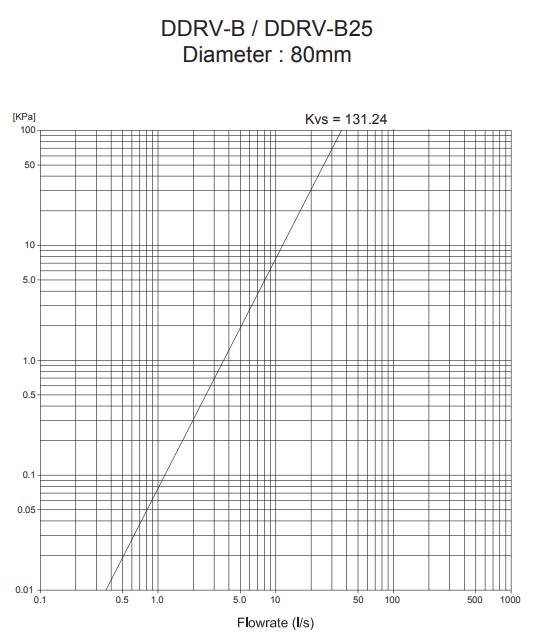

| 80 | 310 | 270 | 200 | 20 | 131.24 |

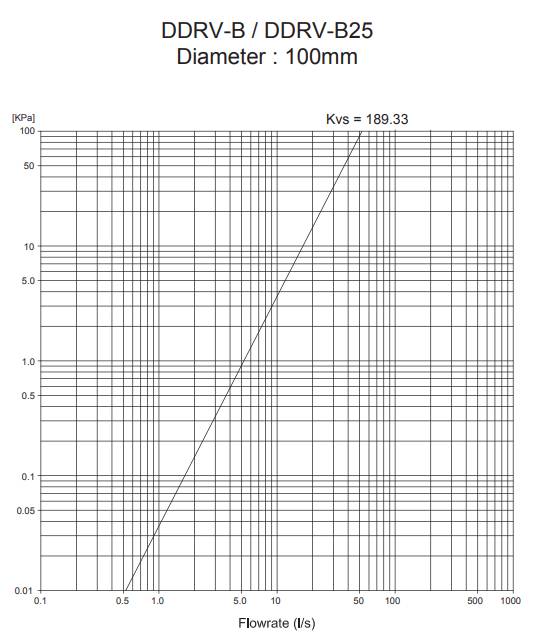

| 100 | 350 | 310 | 240 | 29 | 189.33 |

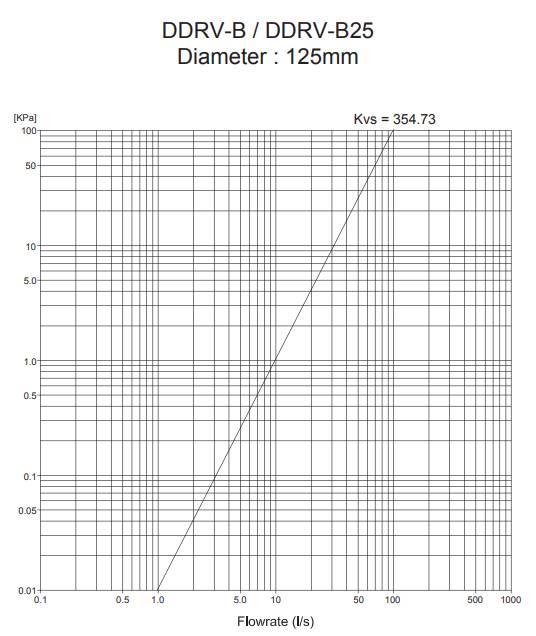

| 125 | 400 | 340 | 290 | 40 | 354.73 |

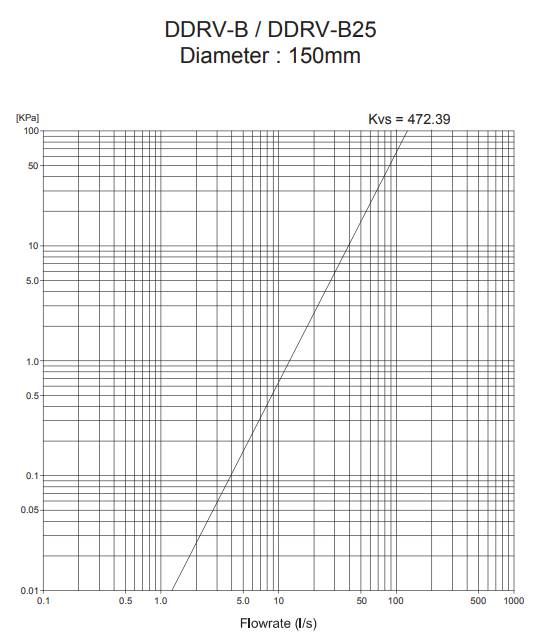

| 150 | 480 | 340 | 290 | 52 | 472.39 |

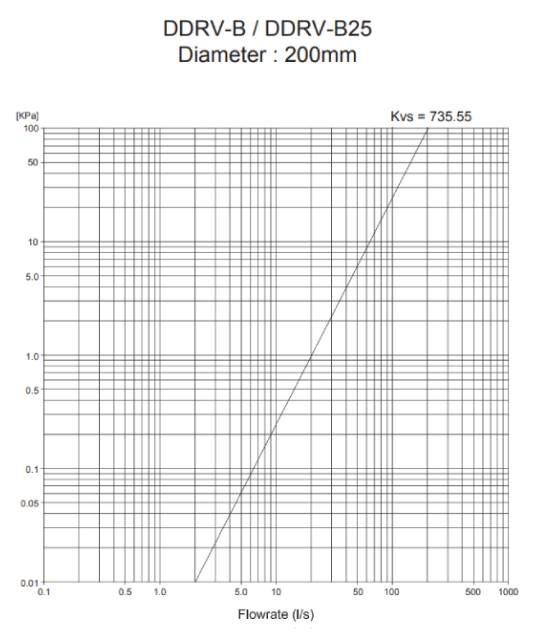

| 200 | 600 | 537 | 350 | 113 | 735.55 |

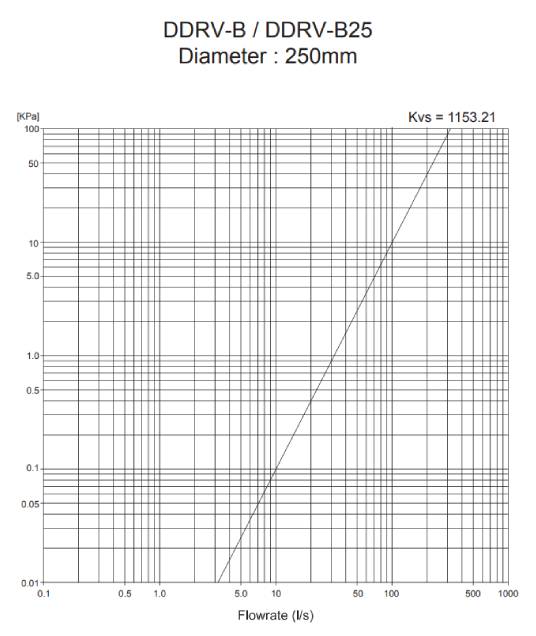

| 250 | 730 | 570 | 420 | 185 | 1153.21 |

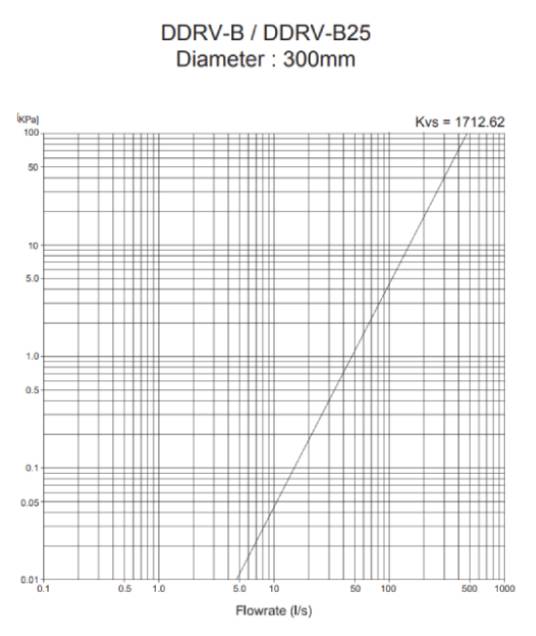

| 300 | 850 | 690 | 420 | 248 | 1712.62 |

Note: Kvs at fully open position.

• The Double Regulating Valve shall be installed with the arrow marking on the valve body in accord to the same flow direction in the pipe. It may be installed at any angle.

• The gasket must be assembled between the flanges when the valve is installed. It can ensure that the valve is concentric with the pipe and the exact measurement data can be read.

• Avoid welding with pipe while it is connected. Tighten flanges bolts alternately, diagonally and repeatedly with the same force.

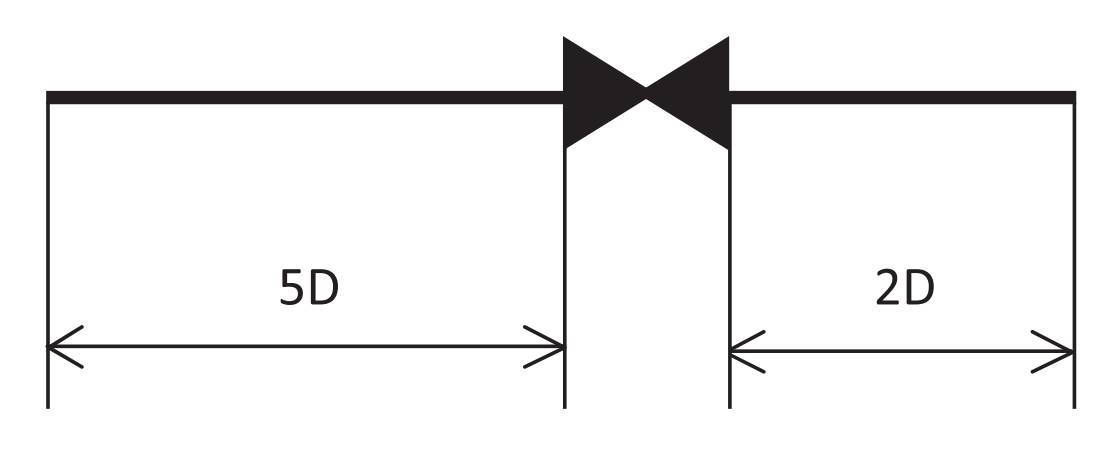

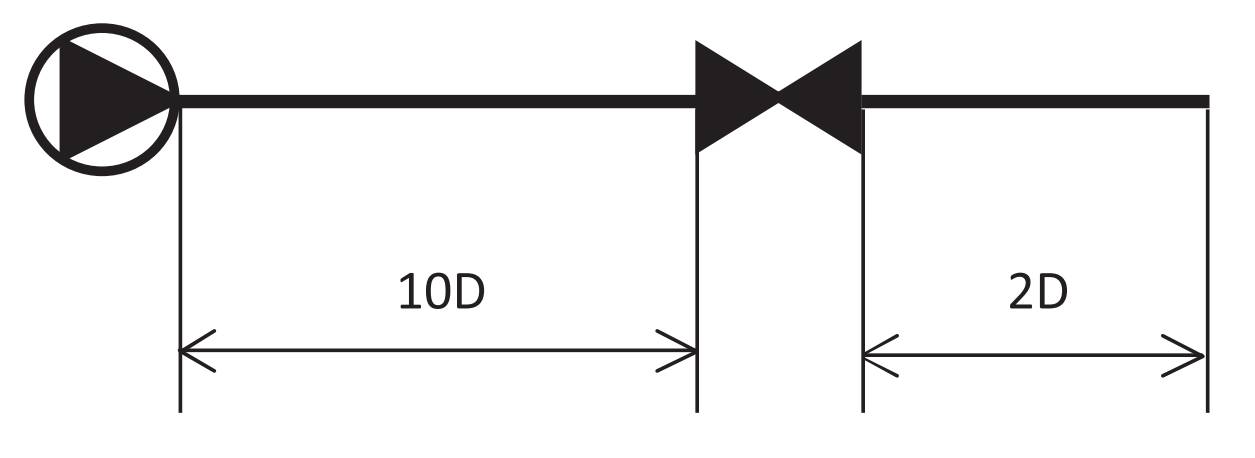

• Up and down stream from the valve is required to avoid turbulence which will affect the accuracy.