- marketing-sales@tozen.com

- +6327 116 4865

- 0917 569 2698

- 0917 6271947

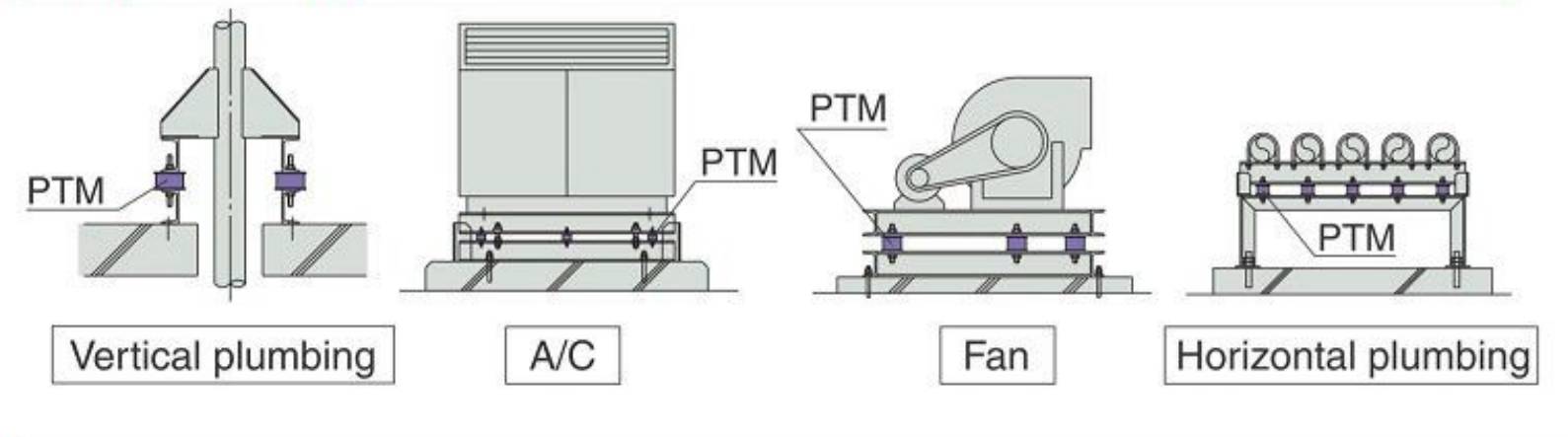

Round Vibration Proof Rubber Versatility and low cost.

Wide load range

Multiple use and low cost

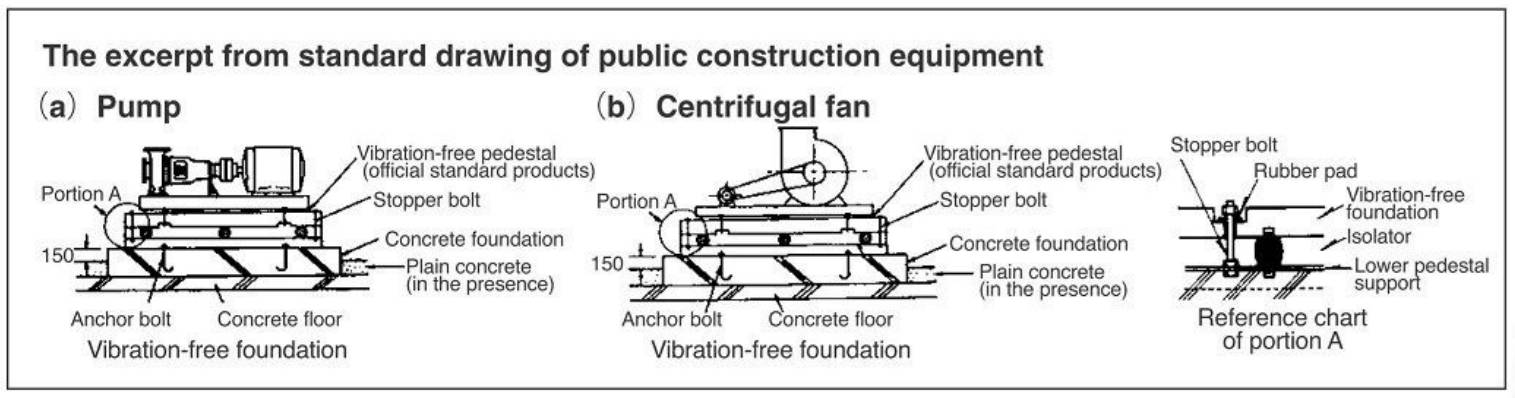

Floor type vibration proof rubber for pump, A/C, fan, electric motor, compressor, vertical/horizontal plumbing. The most basic type of vibration proof rubber. Usually, this rubber is found between upper and lower steel frame.

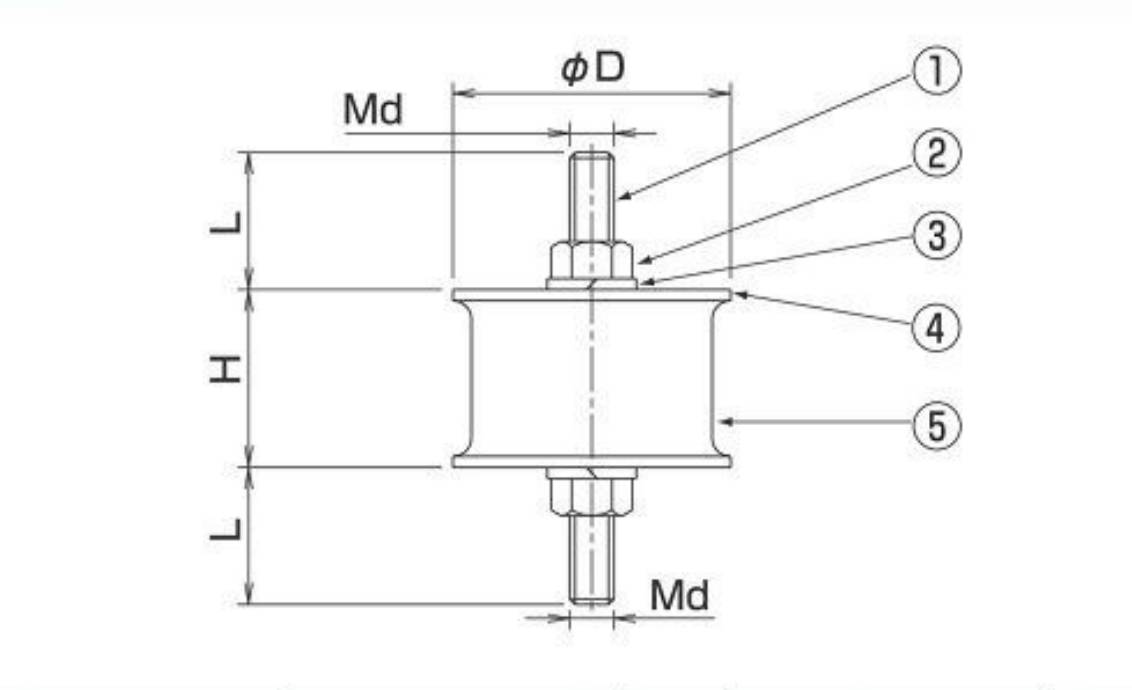

| No. | Parts | Material |

|---|---|---|

| 1 | Attachment bolt | SS400 |

| 2 | Attachment nut | SS400 |

| 3 | Spring washer | SWRH |

| 4 | Metal fittings | SS400 |

| 5 | Rubber body | CR (chloroprene) |

•The metal component is covered by electrolytic zinc-coated

| Type | Body dimensions (mm) | Static spring constant N/mm (kgf/mm) |

Load range of usage N (kgf) |

Natural frequency Hz |

|||

|---|---|---|---|---|---|---|---|

| D | H | L | Md | ||||

| PTM-01 | 20 | 15 | 18 | M6 | 167 (17) | 98~245 (10~25) | 23~15 |

| PTM-02 | 25 | 18 | 18 | M6 | 164 (17) | 196~392 (20~40) | 17~12 |

| PTM-04 | 35 | 26 | 23 | M8 | 181 (18) | 294~735 (30~75) | 14~8.9 |

| PTM-06 | 45 | 34 | 23 | M8 | 202 (21) | 588~1079 (60~110) | 11~7.8 |

| PTM-08 | 55 | 40 | 32 | M10 | 290 (30) | 785~1716 (80~175) | 11~7.4 |

| PTM-09 | 66 | 34 | 37 | M12 | 647 (66) | 1373~3138 (140~320) | 12~8.2 |

| PTM-10 | 76 | 41 | 37 | M12 | 612 (62) | 2550~3923 (260~400) | 8.8~7.1 |

| PTM-11 | 91 | 49 | 37 | M12 | 689 (70) | 3138~5394 (320~550) | 8.4~6.4 |

| PTM-12 | 112 | 66 | 47 | M16 | 842 (86) | 4413~9316 (450~950) | 7.8~5.4 |

| PTM-13 | 152 | 69 | 52 | M20 | 1821 (186) | 7845~19613 (800~2000) | 8.7~5.5 |

Dynamic spring constant of vibration control rubber is 1.3 times higher than that of a static one.

This brochure may be revised without prior notice. We apologize in advance for any inconvenience this may cause.