- marketing-sales@tozen.com

- +6327 116 4865

- 0917 569 2698

- 0917 6271947

Achievements

Having been used in more than 20 countries for over 30 years, TOZEN brand products proudly demonstrate their popularity.

Reliability

Unparalleled durability is guaranteed by the distinctive and strict design standards of TOZEN.

Quality

Manufactured in TOZEN’s own factory under thorough control with ISO9001 quality management system.

Durability

Reciprocating pressure test for 20,000 cycles or above.

● This product is mainly applicable for piping systems in commercial and industrial buildings and plants.

● Applicable fluids are exclusively water including cold water, warm water, cooled water, sea water, etc.

● This product can not be used for pool water, oil, or boiled water.

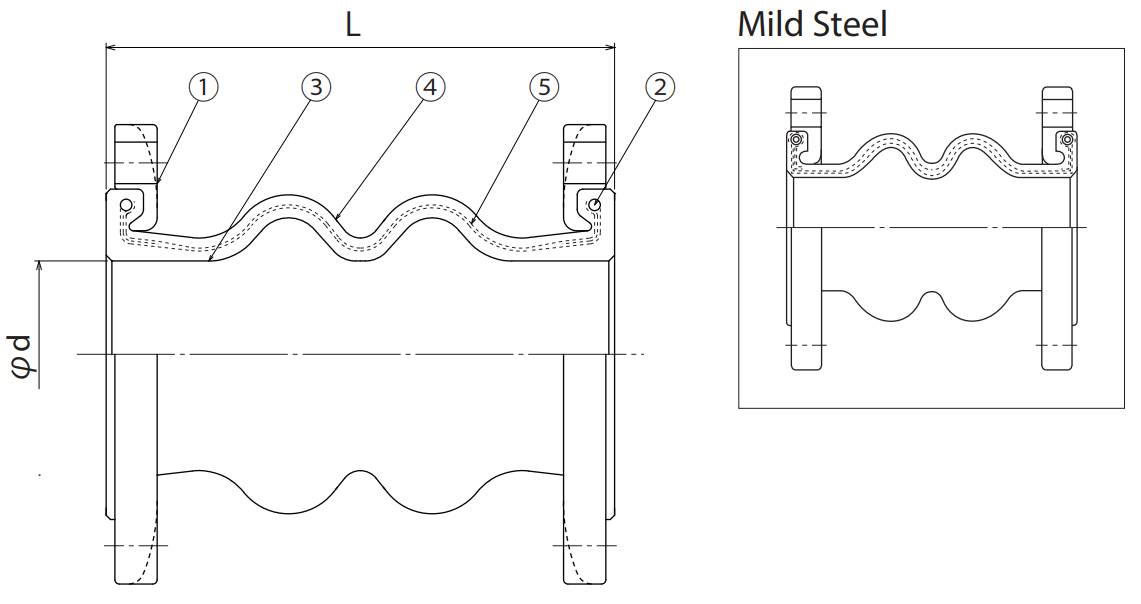

| No. | Parts | Material |

|---|---|---|

| 1 | Flange | Ductile Iron / Mild Steel |

| 2 | Reinforcing Ring | Carbon Steel |

| 3 | Inner Rubber | Synthetic Rubber |

| 4 | Outer Rubber | Synthetic Rubber |

| 5 | Reinforcing Cord | Synthetic Fiber |

|

Flange compatible

dimension

|

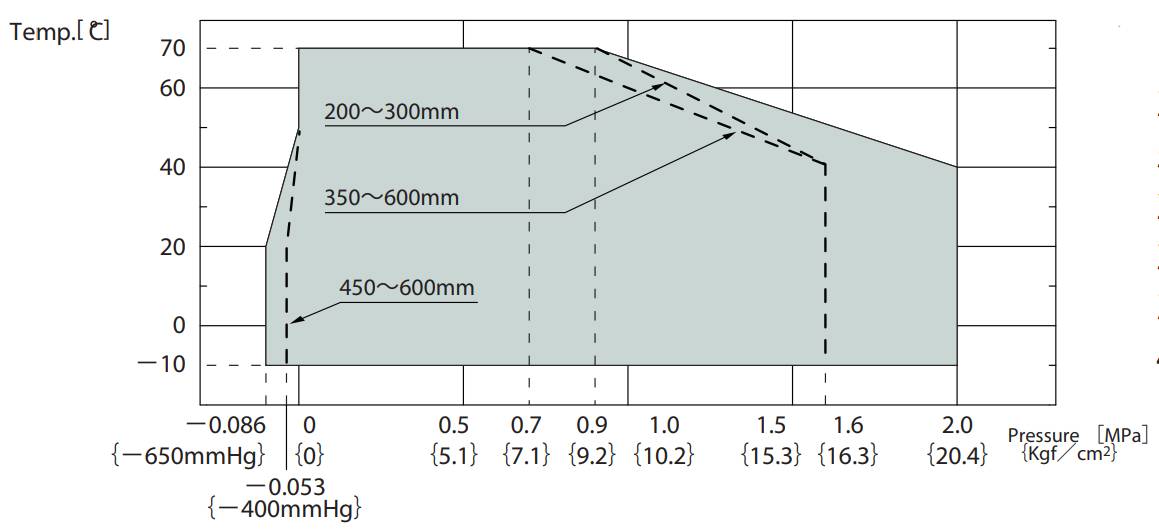

Standard | JIS10K / ANSI150 / PN16 |

| Other | Please consult us. | |

| Material | Standard |

Mild Steel / Ductile Iron

(For 350mm~600mm and ANSI150 32mm is mild steel only)

|

| Can be changed |

○ SUS304

|

|

| ○ SUS316 |

| Nominal Dia. | Dimension [mm] | Mass [Kg] | Allowable Movement [mm] | Installation Tolerances [mm] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | L | φd | T.M. | A.E. | A.C. | A.M. | T.M. | A.E. | A.C. | A.M. | |

| 32 | 1 1/4 | 175 | 35 | 3.3 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5 |

| 40 | 1 1/2 | 175 | 35 | 3.9 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5 |

| 50 | 2 | 175 | 45 | 5.0 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5 |

| 65 | 2 1/2 | 175 | 60 | 6.1 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5 |

| 80 | 3 | 175 | 70 | 7.4 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5 |

| 100 | 4 | 225 | 95 | 8.6 | 25 | 15 | 30 | 20° | 10 | 3 | 6 | 7.5 |

| 125 | 5 | 225 | 120 | 11 | 25 | 15 | 30 | 20° | 10 | 3 | 6 | 7.5 |

| 150 | 6 | 225 | 145 | 14 | 25 | 15 | 30 | 20° | 10 | 3 | 6 | 7.5 |

| 200 | 8 | 325 | 195 | 22 | 30 | 20 | 40 | 20° | 12 | 3 | 6 | 7.5 |

| 250 | 10 | 325 | 245 | 32 | 30 | 20 | 40 | 20° | 12 | 3 | 6 | 7.5 |

| 300 | 12 | 325 | 290 | 42 | 30 | 20 | 40 | 20° | 12 | 3 | 6 | 7.5 |

| 350 | 14 | 250 | 340 | 56 | 15 | 15 | 20 | 15 |

6 | 3 | 6 | 7.5 |

| 400 | 16 | 250 | 390 | 66 | 15 | 15 | 20 | 15 |

6 | 3 | 6 | 7.5 |

| 450 | 18 | 275 | 440 | 67 | 15 | 15 | 20 | 15 |

6 | 3 | 6 | 7.5 |

| 500 | 20 | 275 | 490 | 83 | 15 | 15 | 20 | 15 |

6 | 3 | 6 | 7.5 |

| 600 | 24 | 300 | 590 | 123 | 15 | 15 | 20 | 15 |

6 | 3 | 6 | 7.5 |

● Mass indicates only the case with PN16 (Mild Steel) flanges.

● Please use within allowable displacement range .

● The installation allowance is included in the allowable displacement.

(allowable displacement = installation displacement + operation displacement)

● As shown in chart are data of non-concurrent displacement, please make correction for concurrent displacements.

For correction method, refer to “Attention for handling or “TOZEN HP” (http://www.tozen.com)

Note: The content of this catalog is subject to change without prior notice.