- marketing-sales@tozen.com

- +6327 116 4865

- 0917 569 2698

- 0917 6271947

Spring Vibration Isolating Hanger, Spring And Rubber Vibration Isolating Hanger

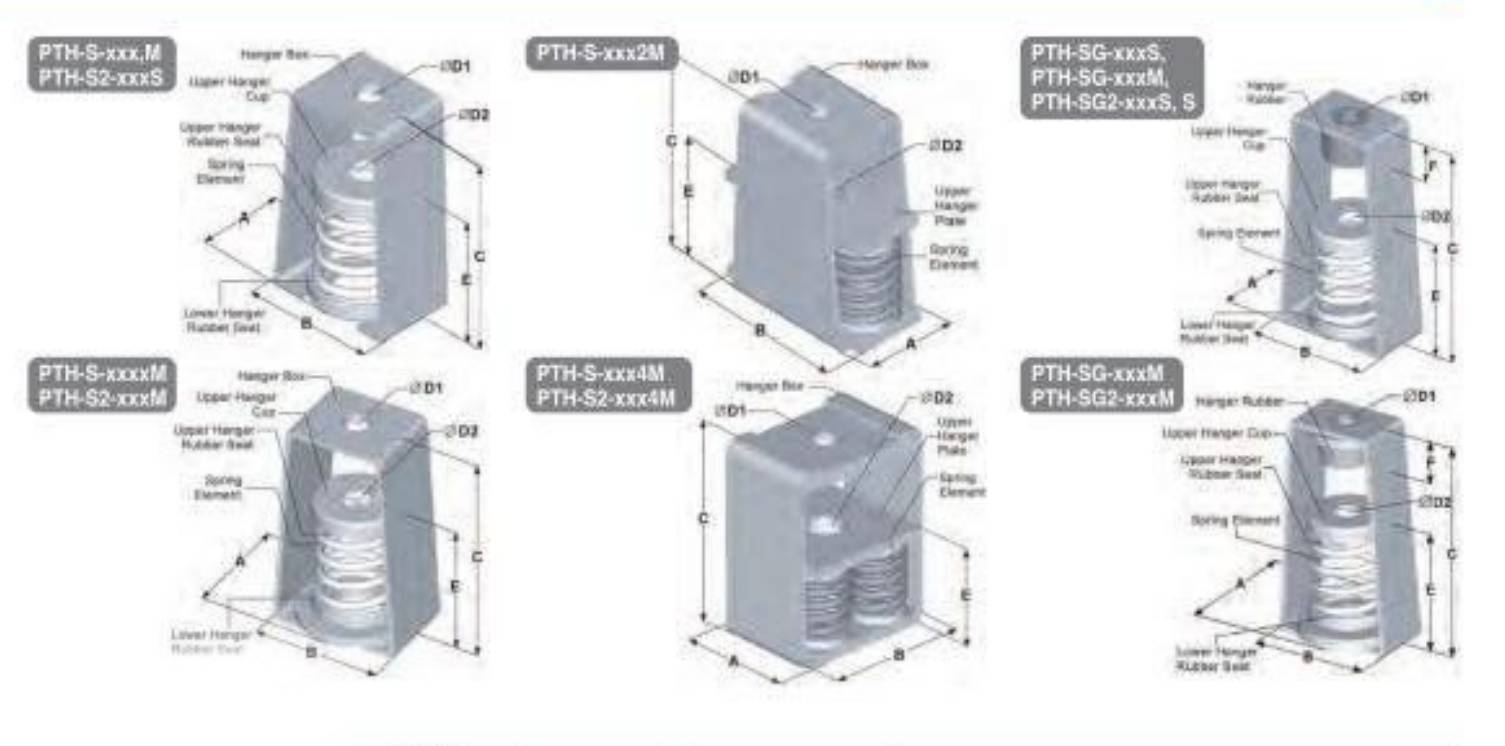

TOZEN PTH-S Series vibration isolating hangers consist of a steel box incorporated with a free standing-laterally stable steel spring with load transfer steel cup and rubber washer. PTH-SG comes in series with noise absorbing hanger rubber properties properties of both materials. Both design permits installation in the hanger rods or at the ceiling.

The designs of the spring elements are comply to JIS 2704 for a semi-permanent use. To assure stability, outside diameter of the springs do not less than 0.8 times of the compressed height of the spring at rated load. All springs are are designed to provide a minimum of 50% overload capacity. Model PTH-S H spring hangers are available with 25 mm and 50 mm deflection with standard load capacity from 25 Kgs to 5,600 Kgs, while PTH-SG spring and rubber hangers are available with load capacity up to 825 Kgs. PTH-S and PTH-SG series vibration isolating hangers are recommended for the isolation of vibration produced by suspended mechanical equipment, low speed suspended fans, transformers, ductwork, piping, etc.

Tozen PTH-S and PTH-SG hangers are used to isolate suspended sources of both audible and inaudible noise and vibration. Suspended mechanical equipment such as in-line fans, cabinet fans, piping and ductwork in close proximity to mechanical equipment, are typical uses of TOZEN PTH-S and PTH-SG hangers. Standard PTH-S and PTH-SG hangers are shipped fully assembled and ready for installation in threaded metal rod suspension systems. Tozen PTH-S and PTH-SG hangers can be provided with labor saving accessories for adaptation to wire or strap suspension system. Both Model PTH-S and PTH-SG saving hangers may be factory preloaded or provided with positioning plate for ease in erecting piping at a fixed elevation. Higher load capacities, larger deflections and 30 degree ARC capacity available.

Type 1, Vibration isolators for suspended equipment, with minimum static deflection requirement exceeding of 6 mm shall be hangers consisting of a free standing, laterally stable steel spring with load transfer steel cup with rubber washer in series, assembled in a welded steel box. The spring elements shall have an outside diameter not less than 0.8 times of the compressed height of the spring at rated load. All springs shall be designed to provide a minimum of 50% overload capacity. Vibration isolating hangers shall be Model PTH-S as manufactured by Tozen Corporation.

Type2, Vibration isolators for suspended equipment with minimum static deflection requirement exceeding 6 mm and where both high and low frequency vibrations are to be isolated, shall be hangers consisting of a laterally stable steel spring in series with a mounted noise absorbing rubber insert, assembled in a welded steel box. The spring elements shall have a outside diameter not less than 0.8 times of the compressed height of the spring at rated load. The combination vibration isolating hangers shall be Model PTH-SG, as manufactured by Tozen Corporation.

PTH-S TYPE

25mm DEFLECTION

| MODEL | RATED CAPACITY | SPRING CONSTANT (kg/mm) |

SPRING COLOR | DIMENSION (mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (Lbs) | A | B | C | D1 | D2 | E | F | |||

| PTH-S-10S | 10 | 22 | 0.4 | GREEN | 58 | 85 | 145 | 13 | 15 | 92 | – |

| PTH-S-15S | 15 | 33 | 0.6 | BLUE | |||||||

| PTH-S-25S | 25 | 55 | 1 | WHITE | |||||||

| PTH-S-35S | 35 | 77 | 1.4 | YELLOW | |||||||

| PTH-S-50S | 50 | 110 | 2 | ORANGE | |||||||

| PTH-S-80S | 80 | 176 | 3.2 | VIOLET | |||||||

| PTH-S-120S | 120 | 264 | 4.8 | RED | |||||||

| PTH-S-175S | 175 | 385 | 7 | SILVER | 58 | 85 | 145 | 15 | 15 | 92 | – |

| PTH-S-225S | 225 | 495 | 9 | BROWN | |||||||

| PTH-S-300M | 300 | 60 | 12 | RED | 84 | 120 | 180 | 17 | 18 | 115 | – |

| PTH-S-450M | 450 | 990 | 18 | GREEN | |||||||

| PTH-S-600M | 600 | 1320 | 24 | SILVER | 105 | 125 | 200 | 25 | 18 | 123 | – |

| PTH-S-825M | 825 | 1815 | 33 | BROWN | |||||||

| PTH-S-1100M | 1100 | 2420 | 44 | BLUE | |||||||

| PTH-S-1202M | 1200 | 2640 | 48 | SILVER | 124 | 225 | 278 | 32 | 32 | 146 | – |

| PTH-S-1652M | 1650 | 3630 | 66 | BROWN | |||||||

| PTH-S-2202M | 2200 | 4840 | 88 | BLUE | |||||||

| PTH-S-2802M | 2800 | 6160 | 112 | BLUE+BROWN | |||||||

| PTH-S-3304M | 3300 | 7260 | 132 | BROWN | 195 | 235 | 300 | 36 | 36 | 148 | – |

| PTH-S-3604M | 3600 | 7920 | 144 | BROWN+SILVER | |||||||

| PTH-S-4404M | 4400 | 9680 | 176 | BLUE | |||||||

| PTH-S-5604M | 5600 | 12320 | 224 | BLUE+BROWN |

PTH-S2 TYPE

50mm DEFLECTION

| MODEL | RATED CAPACITY | SPRING CONSTANT (kg/mm) |

SPRING COLOR | DIMENSION (mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (Lbs) | A | B | C | D1 | D2 | E | F | |||

| PTH-S2-25S | 25 | 55 | 0.5 | WHITE | 84 | 120 | 210 | 15 | 18 | 135 | – |

| PTH-S2-35S | 35 | 77 | 0.7 | YELLOW | |||||||

| PTH-S2-50S | 50 | 110 | 1 | ORANGE | |||||||

| PTH-S2-80S | 80 | 176 | 1.6 | VIOLET | |||||||

| PTH-S2-125S | 125 | 275 | 2.5 | RED | |||||||

| PTH-S2-175S | 175 | 385 | 3.5 | SILVER | |||||||

| PTH-S2-250S | 250 | 550 | 5 | BROWN | |||||||

| PTH-S2-175M | 175 | 385 | 3.5 | ORANGE | 105 | 140 | 255 | 21 | 24 | 168 | – |

| PTH-S2-245M | 245 | 539 | 4.9 | VIOLET | |||||||

| PTH-S2-350M | 350 | 770 | 7 | RED | |||||||

| PTH-S2-525M | 525 | 1155 | 10.5 | GREEN | |||||||

| PTH-S2-750M | 750 | 1650 | 15 | SILVER | |||||||

| PTH-S2-1052M | 1050 | 2310 | 21 | GREEN | 146 | 260 | 235 | 32 | 32 | 190 | – |

| PTH-S2-1502M | 1500 | 3300 | 30 | SILVER | |||||||

| PTH-S2-2102M | 2100 | 4620 | 42 | SILVER+BROWN | |||||||

| PTH-S2-3004M | 3000 | 6600 | 60 | SILVER | 222 | 260 | 325 | 52 | 38 | 194 | – |

| PTH-S2-4204M | 4200 | 9240 | 60 | SILVER+BROWN |

PTH-SG TYPE

25mm DEFLECTION

| MODEL | RATED CAPACITY | SPRING CONSTANT (kg/mm) |

SPRING COLOR | DIMENSION (mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (Lbs) | A | B | C | D1 | D2 | E | F | |||

| PTH-SG-25S | 25 | 55 | 1.0 | WHITE | 58 | 85 | 180 | 11 | 15 | 92 | 28 |

| PTH-SG-35S | 35 | 77 | 1.4 | YELLOW | |||||||

| PTH-SG-50S | 50 | 110 | 2.0 | ORANGE | |||||||

| PTH-SG-80S | 80 | 176 | 3.2 | VIOLET | 16 | 32.5 | |||||

| PTH-SG-120S | 120 | 264 | 4.8 | RED | |||||||

| PTH-SG-300M | 175 | 385 | 7.0 | SILVER | |||||||

| PTH-SG-450M | 300 | 660 | 12 | RED | 84 | 130 | 220 | 18 | 18 | 115 | 44 |

| PTH-SG-600M | 450 | 990 | 18 | GREEN | |||||||

| PTH-SG-825M | 600 | 1320 | 24 | SILVER | 120 | 170 | 270 | 20 | 24 | 124 | 56 |

| PTH-SG-175S | 825 | 1815 | 33 | BROWN |

PTH-SG2 TYPE

50mm DEFLECTION

| MODEL | RATED CAPACITY | SPRING CONSTANT (kg/mm) |

SPRING COLOR | DIMENSION (mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (Lbs) | A | B | C | D1 | D2 | E | F | |||

| PTH-SG2-25S | 25 | 55 | 0.5 | WHITE | 84 | 140 | 235 | 11 | 18 | 135 | 29.5 |

| PTH-SG2-35S | 35 | 77 | 0.7 | YELLOW | |||||||

| PTH-SG2-50S | 50 | 110 | 1 | ORANGE | |||||||

| PTH-SG2-80S | 80 | 176 | 1.6 | VIOLET | 16 | 32.5 | |||||

| PTH-SG2-125S | 125 | 275 | 2.5 | RED | |||||||

| PTH-SG2-175M | 175 | 385 | 3.5 | ORANGE | 120 | 160 | 290 | 18 | 24 | 168 | 50 |

| PTH-SG2-245M | 245 | 539 | 4.9 | VIOLET | |||||||

| PTH-SG2-350M | 350 | 770 | 7 | RED | |||||||

| PTH-SG2-525M | 525 | 1155 | 10.5 | GREEN | 120 | 180 | 0 | 20 | 24 | 168 | 56 |

| PTH-SG2-750M | 750 | 1650 | 15 | SILVER |

NOTE-1: All springs have an minimum additional travel to solid equal to 50% of rated load.

NOTE-2: Please refer to relevant brochure or consult factory for greater deflection and loading.

NOTE-3: Spring constant applies to spring only.

NOTE-4:Please consult factory for pre-compressed model and 30 degree arc capacity

1) Consider the height and location of the hanger and prepare the upper and lower hanging rod(bolt) in same proper length.

2) Attach the upper hanging rod(bolt) to the ceiling.

3) Connect the lower hanging rod (bolt) to the hanger. Pre-compress the hanger spring element (Approx. 10 mm) by tighten a restrain nut and washer at the bottom of the hanger.

4) Attach the hanger to the upper hanging rod(bolt)

5) Attach the hanging rod (bolt) to the pipe, duct or equipment bracket.

6) Install the hangers by repeating instruction 1-5

7) After the pipe or equipment is filled with water, release the restraint nut. Leveling adjust the hanger by the nut at the top of the element to obtain even level installation.

8) Final check the spring hanger in a proper deflection and don’t install the hanging rod(bolt) in a inclined position.

Note: The content of this catalog is subject to change without prior notice.