- marketing-sales@tozen.com

- +6327 116 4865

- 0917 569 2698

- 0917 6271947

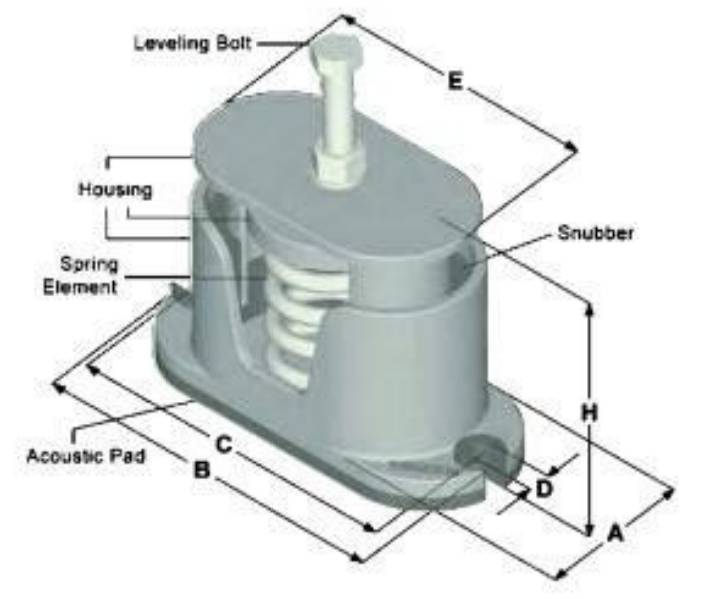

PTM-C series spring vibration isolators are designed and constructed for high deflection, with laterally stable spring elements and assembled into telescoping cast iron housing. Each cast iron housing is equipped with an 8 mm thick, ribbed, noise absorbing pad that is bonded to the bottom. Each isolator has an internal or external adjusting/leveling bolt as a part of the top assembly. The ribbed, noise absorbing pad has an integrated resilient washer that prevents the transmission of noise and vibration from the contact of the bolt and mounting base plate to the structure. Holes or slots are provided in all of the isolators for bolting the isolator to the structure. Model PTM-C series spring isolators are available in standard deflection of 25 and 50 mm with load capacity from 200 Kgs to 1,400 Kgs (440 to 3080 lbs). Tozen Model PTM-C spring isolators are typically used to isolate vibration produced by mechanical, industrial, or process machinery, where more damping is required and less motion can be tolerated than with free standing spring isolators.

TOZEN Model PTM-C spring isolators are used to isolate high and low frequency vibration generated by floor mounted mechanical equipment located in non-critical and semi-critical areas.

Model PTM-C spring isolators are typically used to isolate the vibration produced by light weight mechanical equipment having the lowest operating speed of 1,200 rpm, located on grade supported slabs, or short structural floor spans, or when the isolator to equipment connection is such that a leveling bolt can be extended above the mount and act as a leveling and attachment bolt for the supporting equipment.

The vibration isolators shall be constructed with cast iron housed steel spring elements, a load cap and rubber sponge snubbers. The snubbers shall be designed to stabilize the isolator and prevent metal on metal contact within the top or bottom of the housed section. The top loading plate shall be constructed with a leveling bolt and lock nut.

The housing’s bottom shall be bonded to an 8 mm thick, ribbed, rubber pad and shall be slotted or drilled to allow for the bolting of the isolator to the supporting structure.

Outside diameter of the spring elements shall be greater than 80% of the compressed height of the spring element at the rated load. All spring elements shall be designed to provide a minimum 50% overload capacity.

Spring shall be selected to provide operating static deflections shown on the Vibration Isolation Schedule or as indicated on the project specifications. Springs shall be color coded or otherwise identified to indicate load capacity.

Vibration isolators shall be Model PTM-C as manufactured by Tozen Corporation.

PTM-C TYPE

25mm DEFLECTION ANTI-VIBRATION MOUNTING

| MODEL | RATED CAPACITY | SPRING CONSTANT (kg/mm) |

SPRING COLOR | OPERATING HEIGHT (H) |

(A) | (B) | SLOT PITCH (C) |

SLOT HOLE (D) |

TOP PLATE LENGTH (E) |

LEVELING BOLT (LB) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (Lbs) | ||||||||||

| PTM-C-200M | 200 | 400 | 8 | VIOLET | 145 | 94 | 216 | 194 | 13 | 162 | M1 |

| PTM-C-300M | 300 | 660 | 12 | RED | |||||||

| PTM-C-450M | 450 | 990 | 18 | GREEN | |||||||

| PTM-C-600M | 600 | 1320 | 24 | SILVER | |||||||

| PTM-C-825M | 825 | 1815 | 33 | BROWN | |||||||

| PTM-C-1100M | 1100 | 2420 | 44 | BLUE | |||||||

| PTM-C-1400M | 1400 | 3080 | 56 | BLUE+BROWN |

PTM-C2 TYPE

50mm DEFLECTION ANTI-VIBRATION MOUNTING

| MODEL | RATED CAPACITY | SPRING CONSTANT (kg/mm) |

SPRING COLOR | OPERATING HEIGHT (H) |

(A) | (B) | SLOT PITCH (C) |

SLOT HOLE (D) |

TOP PLATE LENGTH (E) |

LEVELING BOLT (LB) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kgs) | (Lbs) | ||||||||||

| PTM-C2-175M | 175 | 385 | 3.5 | ORANGE | 185 | 110 | 254 | 229 | 16 | 195 | M16 |

| PTM-C2-245M | 245 | 539 | 4.9 | VIOLET | |||||||

| PTM-C2-350M | 350 | 770 | 7 | RED | |||||||

| PTM-C2-525M | 525 | 1155 | 10.5 | GREEN | |||||||

| PTM-C2-750M | 750 | 1650 | 15 | SILVER | |||||||

| PTM-C2-1050M | 1050 | 2310 | 21 | SILVER+BROWN |

NOTE-1: All springs are free standing and laterally stable. (Outside diameter do not less 0.8 times of compressed height)

NOTE-2: Please refer to relevant brochure of factory for greater deflection and loading

NOTE-3: PTM-C type External Levelling Bolt (LB) is suitable for maximum 25 mm bracket or base thickness, please specify for equipment base thicker than 25 mm.

A) For PTM-C (External level adjusted) spring isolators

1.Take out the leveling bolt and lock nut from the top of the isolator.

2.Lift or block up the equipment’s leg or isolator bracket to 5mm higher isolator’s operating height (see catalogue) and slide the isolators into position. Put the leveling bolt & lock nut back into position.

3.Transfer the equipment weight to the spring by taking two clockwise turns on each leveling bolt around the the unit until the springs springs are are compressed compressed just enough to remove blocks.

4. Tighten the lock nut to lock the assembly.

a) When the equipment is not subject to rise to the required height, height saving bracket may be attached to the equipment. The height of bracket connection from the bottom of the base shall be 50mm less than the isolator’s operating height or to keep a 50mm clearance between the ground and equipment.

b) DO NOT install the equipment on the support of free spring; it would cause an insufficient operating height for the spring isolator when the installation is completed.

c) Weight of vertical piping and valves shall be supported by the suspension hangers or other supports.

d) Install the flexible joint at the completion of the installation, following the pre-extension instructions which may be specified or suggested by the flexible joint manufacturer.

e) Where bolting is required, avoid a direct metal contact between bolt and mounting, to prevent transmission of acoustical frequencies; the bolt shank shall be clear in the hole and a rubber washer used under the bolt head. Bolts shall only be tightened a half turn more than hand tight.

Note: The contents of this catalogue are subject to change without notice.